Pressure sensors, whether we're talking about pressure transducers or pressure transmitters, are electromechanical devices used to measure pressure with high accuracy. These devices detect the pressure of air, gases, or liquids and convert that measurement into a usable output (typically an electrical signal such as voltage or current) that can be monitored or processed by other systems and/or devices.

Pressure sensors are essential pressure measurement devices used across a wide range of industries to monitor and control gases and liquids. In HVAC systems, automotive manufacturing, aerospace engineering, medical equipment, and industrial process control, reliable pressure monitoring helps maintain safety, improve efficiency, and ensure long-term system performance.

Transducer, Transmitter, or Sensor

Although there are subtle differences between the terms pressure transducer, pressure transmitter, and pressure sensor, they are used almost interchangeably in practice. Manufacturers and end users seldom make distinctions, since many of these instruments share overlapping functions and capabilities.

- Pressure Transducer: Can provide different types of output signals, but voltage output (commonly 0–5 V) is one of the most widely used. The choice of output depends on the application’s requirements for accuracy, distance, and compatibility with control systems.

These devices are frequently found in HVAC systems, process control applications, and industrial machinery where continuous operation and reliable monitoring are essential. Typical uses include brake pressure monitoring in off-road vehicles and rail systems, oil and fuel pressure measurement in transportation equipment, liquid level monitoring in HVAC pumps, and pressure control in medical devices. - Pressure Transmitter: Build on the function of transducers by conditioning the raw signal. In addition to measuring pressure, a transmitter amplifies, linearizes, and compensates the output—producing standardized signals such as 0–5 V, 0–10 V, or, most commonly, 4–20 mA. This makes them highly reliable for transmitting data over long distances and integrating directly into process control systems.

Because of their robustness and versatility, transmitters are widely used in large-scale processing industries such as chemical production, food and beverage manufacturing, and power generation and distribution. They are also common in HVAC/R systems, industrial equipment manufacturing, and health and safety products. In general, pressure transmitters are the preferred choice wherever signals must remain accurate and stable across long cable runs or electrically noisy environments. - Pressure Sensor: A broad, catch-all term for any device that detects pressure and produces an output signal. Modern devices with digital protocols (e.g., IO-Link or CAN bus) are often simply called “sensors.”

There are other terms as well, such as I/P converters (current-to-pressure) and pressure switches. In the end, it’s common for people to group them all together under the umbrella term “pressure sensors.”

How Does a Pressure Transducer Work?

A step-by-step breakdown:

- Pressure Applied

- Mechanical Deformation

- Electrical Charge

- Signal Conversion

- System Output

-

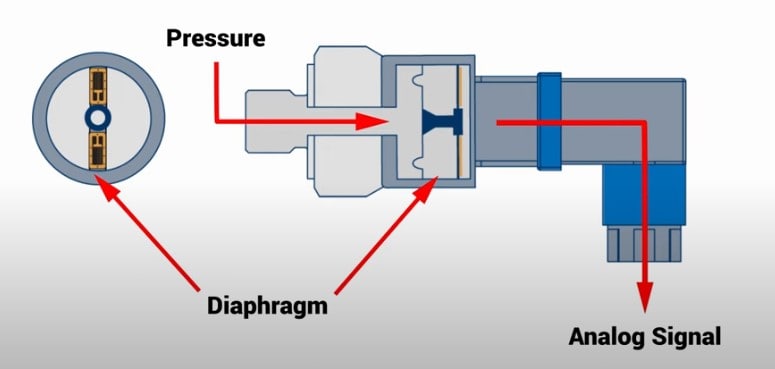

A gas or liquid exerts force against the sensor's diaphragm (a thin, flexible membrane)

-

The diaphragm bends or deflects in proportion to the amount of pressure applied

-

Attached sensing elements—such as strain gauges, piezoelectric crystals, or capacitive plates—detect this deformation and convert it into an electrical change (resistance, charge, or capacitance)

-

The sensor’s internal electronics process this small change and convert it into a standardized electrical output, usually a voltage, current (4–20 mA), or digital signal.

-

The resulting signal is sent to a display, controller, or data acquisition system, where it can be monitored, recorded, or used for automatic control.

Pressure Transducer Types

Pressure transducers are not one-size-fits-all devices: different designs are optimized for specific applications, environments, and measurement ranges. While all transducers share the basic purpose of converting pressure into an electrical signal, they do so using different sensing principles.

Among the many designs available, strain-gauge (piezoresistive) and capacitive transducers are the two most widely used types. Understanding how these work, as well as where they excel, can help you select the right device for your application, whether you’re monitoring subtle atmospheric changes or measuring extreme hydraulic pressures.

Strain-Gauge (Piezoresistive)

These transducers use a thin diaphragm with strain gauges bonded in a Wheatstone bridge configuration. When pressure is applied, the diaphragm flexes, causing minute changes in electrical resistance. The bridge circuit converts this resistance shift into a proportional output signal.

Strain-gauge designs are rugged, stable, and well-suited for static and high-pressure measurements. Their durability and accuracy make them common in industrial automation, automotive systems (like fuel and oil monitoring), aerospace, and hydraulic control. While they perform exceptionally well under high loads, their sensitivity is typically lower than capacitive types, making them less ideal for ultra-low-pressure applications.

Capacitive

In capacitive transducers, a diaphragm and a fixed plate form a capacitor. As pressure deflects the diaphragm, the distance between plates changes, altering capacitance (the ability of an object to store electric charge). Because even tiny deflections produce measurable changes, capacitive sensors provide high sensitivity and resolution, especially at low or differential pressures.

These designs are often chosen for applications where detecting small changes matters, such as HVAC system monitoring, cleanroom pressure control, barometric measurements, and environmental monitoring. Their low power consumption and excellent sensitivity make them particularly valuable in scenarios where precision at low pressures is more important than withstanding extreme loads.

Types of Pressure Signal Outputs

When a pressure transducer is powered and exposed to pressure, it produces an electrical signal proportional to that pressure. The most common output formats are millivolt (mV/V), voltage, current (4–20 mA), and digital. The right choice depends on cable length, electrical noise, available power, and the host system’s interface.

Millivolt (Ratiometric) Outputs

The bridge output (in mV) scales with the excitation voltage (mV/V). Because the signal is small, a regulated supply, short cable runs, and low-noise environments are recommended. With minimal electronics, these sensors are compact, rugged, and handle harsh conditions well.Best for: Short distances, low noise environments, and applications prioritizing robustness and small size.

Voltage Outputs

Typical ranges are 0–5 V, 0–10 V, or 1–5 V. Internal signal conditioning produces a higher-level output that’s less sensitive to supply variation and electrical noise than mV signals. Cable lengths are moderate; good shielding and grounding improve performance.

Best for: Industrial settings with some electrical noise where a simple, high-level analog input is available.

Current loop output (typically 4–20 mA)

A two-wire, loop-powered transmitter modulates current rather than voltage, making the signal highly resistant to electrical interference and voltage drop over long cables. It’s the de-facto standard in process industries (0–20 mA exists but 4–20 mA is most common).

Best for: Electrically noisy environments and long cable runs (hundreds of meters/over 1000 ft), especially in process control.

Digital Outputs (Smart Transducers)

Digital transducers communicate via protocols such as Modbus/RS-485, CAN, HART, I²C, or SPI. Beyond pressure, they can report metadata (e.g., calibration, serial/asset info), log data, trigger alarms, and support remote configuration. Transmission distance and topology depend on the protocol and cabling, often suitable for long runs.

Best for: Long distances, advanced diagnostics, multi-parameter data, and integration with modern controls/SCADA.

Inovative Solutions from DwyerOmega

MM Series Configurable Pressure Transducers

The MM Series offers unmatched flexibility and accuracy, with over one million possible configurations to match specific application needs. Using micro-machined piezoresistive technology, these sensors achieve up to ±0.05% accuracy with excellent stability across temperature ranges.

Built with a rugged stainless-steel diaphragm, glass-to-metal seals, and silicone-oil coupling to a silicon strain-gage bridge, the MM Series delivers long-term reliability in demanding environments. Typical applications include engine testing, fluid level monitoring, leak detection, process control, and sanitary measurement in food and biopharma systems.

Connect with a DwyerOmega Expert Today!