What makes a bicycle truly high-performing? Materials and design certainly matter, but one of the most critical factors is how well the frame withstands the forces of real-world riding.

Load and vibration testing in bicycle manufacturing ensures that every frame can handle rider weight, road vibrations, and lateral motion without compromising safety or performance. By simulating these stresses under controlled conditions, manufacturers gain precise insights into how a frame responds, paving the way for stronger, more reliable, and high-performance bicycles.

Why Load and Vibration Testing Matters

A bicycle frame experiences complex forces while in motion. From the downward load of the rider’s weight to lateral vibrations on uneven terrain, each stress point influences the frame’s durability, comfort, and safety. Without accurate testing, manufacturers risk producing bikes that:

- Fail prematurely under stress

- Generate excessive vibration and rider fatigue

- Do not meet performance or industry standards

By implementing repeatable, data-driven testing systems, manufacturers can validate designs, compare materials, and refine their products before they ever reach the market.

The Testing Process

A typical load and vibration test for bicycles involves the following steps:

- Mounting the Frame – The bicycle is secured on a test bench

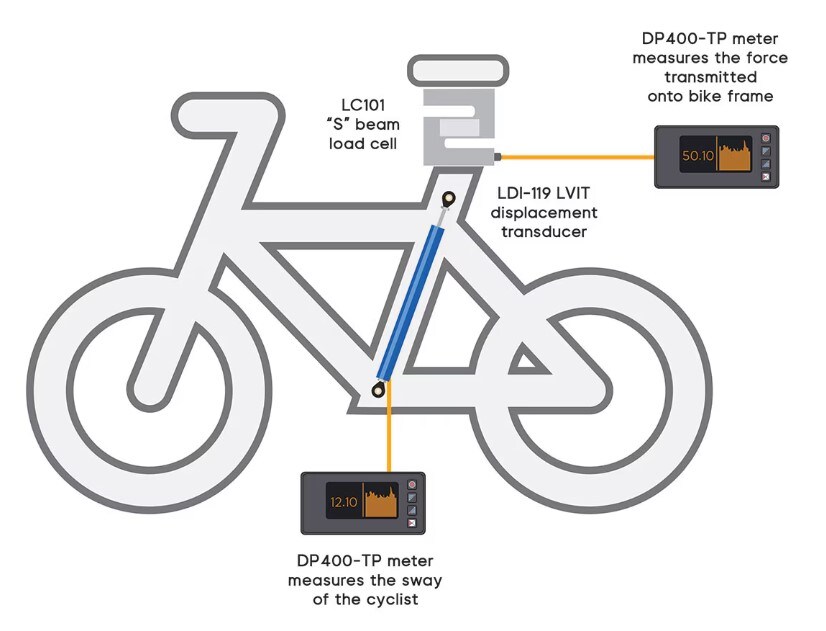

- Measuring Forces with Load Cells – An S-Beam load cell is installed between the frame and seat to qantify tension and compression forces

- Capturing Strain Data – Linear strain gauges are applied to key frame elements to measure deformation and stress distribution

- Measuring Vibrations – Accelerometers detect vibrations across the frame

- Tracking Motion – A linear displacement transducer monitors sway and rider-like movements

- Simulating Real-World Use – The bike is subjected to side-to-side motions and dynamic loads to replicate cycling conditions

- Logging Data – Data loggers collect, store, and transfer high-resolution data to any prefered platform for analysis

This comprehensive setup ensures engineers receive granular, repeatable data that reflects how the frame will perform under real use.

Results and Benefits

By integrating these steps, manufacturers can:

- Validate frame strength and performance before market release

- Optimize designs to reduce weak points and improve rider comfort

- Ensure compliance with performance standards and safety regulations

- Generate repeatable, high-resolution data for design validation and product comparisons

For bicycle companies, this means higher quality, more reliable bikes. For riders, it means confidence and safety on every ride.

Innovative Solutions from DwyerOmega

LC103B Series S-Beam Load Cells

Compact, stainless steel, and IP67-rated, these C103B Series S-Beam Load Cells measure both tension and compression. With capacities from 25 to 20,000 lbs, they meet OIML R60 C3 accuracy standards and are widely used in scales, cranes, and testing rigs.

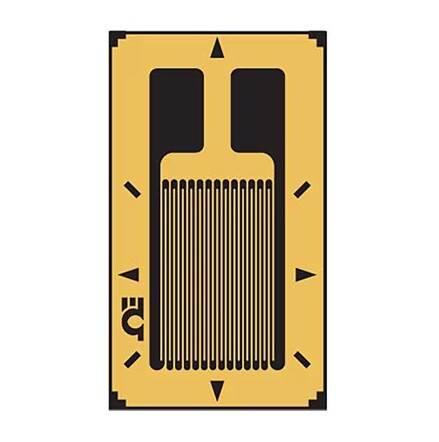

SGD-LINEAR1-AXIS Strain Gages

These Linear Strain Gages feature etched constantan foil sealed in polyimide film provides accurate strain measurements across static and dynamic conditions. These gages are flexible, durable, and designed for precise stress analysis.

ACC787A Accelerometers

These Low-Profile, Stainless Steel Accelerometers deliver reliable vibration data even in harsh environments. Rugged and corrosion-resistant, they capture vibration signatures crucial for frame design validation.

LDI-119 LVIT Position Sensors

These LVIT Linear Position Sensors are designed for accurate displacement measurement. With ranges from 25 to 200 mm, they prevent mechanical wear and are easy to install on test rigs.

OM-VIB-101 Vibration Logger

These Compact USB Data Loggers record three-axis acceleration, tilt, and motion. Storing up to 327,600 data points, it provides engineers with an accessible, PC-compatible analysis tool.

DwyerOmega in the Real World

Argon 18: A Passion for Performance

Argon 18 road bikes can be found on the Tour De France, Triathalons, and road races all over the world.Check out the video to see how DwyerOmega has teamed up with the Argon 18 team to become a piece of the puzzle for these powerful bikes.

Connect with a DwyerOmega Expert Today!