Pulse-jet bag filters are widely used in industrial dust collection systems because they allow for continuous operation while maintaining high filtration efficiency. However, when filter bags begin to leak or fail, and the continuity is broken, performance drops quickly and can lead to regulatory issues, product loss, or unplanned downtime.

Understanding how pulse-jet bag filters work, how they are cleaned, and how leakage can be detected early is key to keeping these systems running reliably.

What Is a Pulse-Jet Bag Filter Dust Collector?

A dust collector is a system designed to improve air quality in industrial and commercial environments by capturing dust and airborne particulate. Pulse-jet bag filter dust collectors are one of the most common designs used in applications that require high dust loading capacity, high collection efficiency, or the handling of hazardous materials.

These systems typically support pneumatic conveying processes or protect downstream equipment and personnel by removing particulates from exhaust air streams.

How Pulse-Jet Bag Filter Systems Work

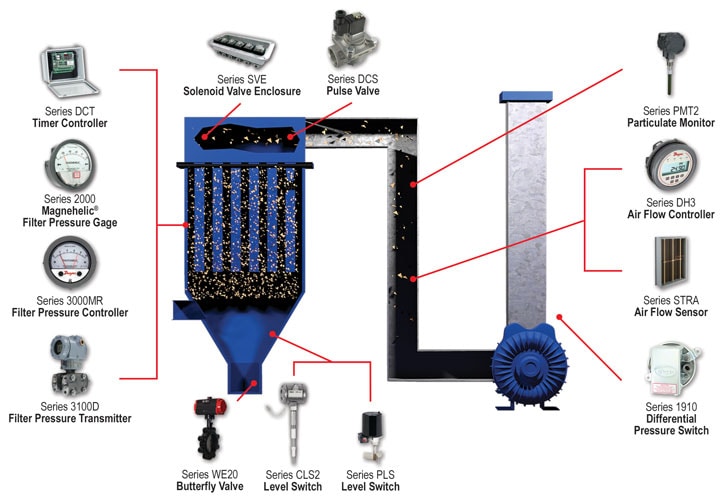

Dust-laden air enters the collector housing through the inlet, where a baffle plate directs heavier particles into the hopper. Finer dust particles remain suspended in the airflow and are drawn toward the filter bags. As air passes through the fabric media, dust is captured on the surface of the bags while clean air moves into the clean air plenum and exits through the outlet duct.

Over time, this dust layer builds up on the filter surface. While a thin dust cake can improve filtration efficiency, excessive buildup increases pressure drop and restricts airflow, making periodic cleaning essential for continuous operation.

Pulse-Jet Cleaning and Pressure Drop Control

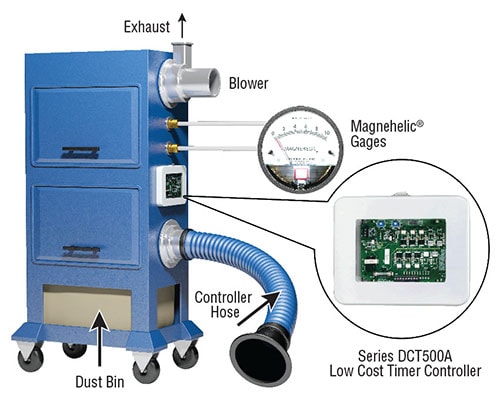

Pulse-jet cleaning is performed using short bursts of compressed air delivered through a blow pipe and nozzle positioned above each filter bag. During a cleaning cycle, a high-pressure air pulse, typically lasting between 100 and 450 milliseconds, is injected downward into the bag.

This sudden burst creates a compression wave that causes the bag to rapidly expand and contract, dislodging accumulated dust from the filter surface. The released dust falls into the hopper below for collection.

Cleaning occurs in rows, with only a portion of the bags pulsed at any given time. This staged approach allows the dust collector to remain online, minimizing or eliminating process downtime.

Monitoring Filter Condition with Differential Pressure

Pressure drop across the filter bags is a primary indicator of dust buildup and overall system health. Differential pressure gauges are commonly installed across the dirty and clean sides of the collector to provide real-time feedback.

When pressure drop reaches a predetermined level, a cleaning cycle can be initiated manually or automatically through a timer controller and solenoid valves. Automated systems use pressure-based setpoints to trigger cleaning only when needed, reducing compressed air consumption and extending filter life.

Maintaining proper pressure drop not only protects airflow and fan performance but also reduces mechanical stress on the filter bags.

Detecting Leaking or Failed Filter Bags

Even with proper cleaning, filter bags can eventually fail due to abrasion, chemical attack, thermal stress, or mechanical damage. When a bag tears or develops a hole, dust bypasses the filtration media and escapes into the clean air plenum and exhaust stream.

Depending on the industry and application, this leakage can result in environmental compliance violations, product loss, or visible emissions at the stack.

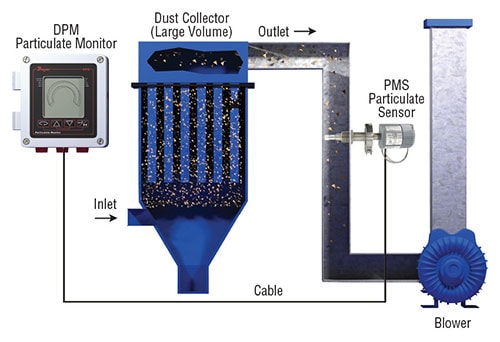

Particulate monitoring systems installed in the exhaust duct provide early detection of leaking or broken bags. These systems measure particulate concentration using induction-based sensing technology and display real-time leakage levels. Programmable alarm thresholds can activate outputs when leakage exceeds acceptable limits, alerting operators to filter problems before they escalate.

Maintaining Continuous Operation and Compliance

Early detection of leaking filter bags allows maintenance teams to intervene before emissions exceed regulatory limits or force a system shutdown. By combining differential pressure monitoring with particulate leakage detection, operators gain visibility into both filter loading and filter integrity.

The benefits of this approach include:

- Maintaining regulatory compliance

- Maximizing product recovery

- Optimizing filtration efficiency

- Preventing unplanned shutdowns and fines

- Reducing environmental impact

Together, these monitoring strategies help ensure pulse-jet bag filter systems continue operating reliably, even as filters age and process conditions change.

Innovative Solutions from

|

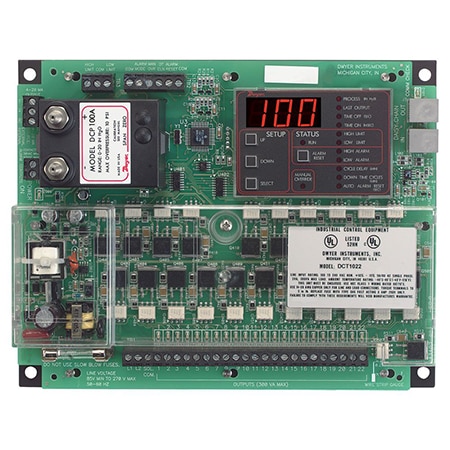

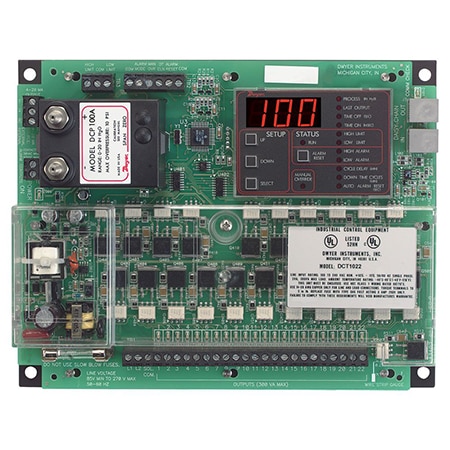

Modular dust collector timer controller designed for pulse-jet cleaning systems. Supports 6, 10, or 22 output channels with automatic expander detection and on-demand or continuous cleaning modes, eliminating the need for external relays, switches, or timers.

|

Buy Now |

|

Weatherproof solenoid valve enclosure designed for use with RSV pilot valves. Available in 6 or 12 valve configurations, with solenoids pre-wired to a terminal block to simplify installation and field wiring.

|

Buy Now |

|

Dust emissions transmitter designed for monitoring particulate levels at dust collector discharge. Uses electrostatic induction sensing to provide a 4 to 20 mA output, with six selectable sensitivity ranges for emissions monitoring and broken bag detection.

|

Buy Now |

|

The 3-in-1 Digihelic® Differential Pressure Controller combines a digital display, control relays, and a transmitter with 4 to 20 mA output. Designed for pressure, velocity, and flow applications, with field calibration, secure menu programming, and 1.5 % accuracy on low ranges.

|

Buy Now |

|

Compact low differential pressure switch for air and non-combustible gas applications, with adjustable set points from 0.07 to 20 in H₂O. Designed for reliable filter monitoring, coil icing detection, and VAV control, with internal range adjustment to prevent tampering.

|

Buy Now |

|

Capacitive level switch for liquids, powders, and bulk materials, featuring PVDF or 316 SS wetted materials and a weatherproof enclosure. Universal 12 to 240 VAC/DC power and selectable failsafe DPDT output support reliable level detection in demanding process environments.

|

Buy Now |

|

Smart differential pressure transmitter for flow, level, and process monitoring applications, featuring push-button zero and span configuration and HART® communication. FM approved for hazardous locations, with high rangeability and thermal compensation for stable, accurate measurements.

|

Buy Now |

|

Mechanical low differential pressure gauge for air and non-corrosive gas applications, providing fast, accurate readings without requiring power. Rugged IP67-rated construction makes it ideal for filter monitoring, air handling, and HVAC systems.

|

Buy Now |