Each day, billions of gallons of wastewater are collected from homes, businesses, and industrial facilities. Wastewater is exactly what you think it is: water that's already been used (sinks, toilets, showers, storm drains, etc.) and requires treatment before it can be resued or released back into the enviornment.

Wastewater contains contaminants such as organic waste, chemicals, and microorganisms. Once collected, it is directed through sewer systems to treatment plants where it can be purified and safely returned to the environment.

From Natural Purification to Modern Treatment

Before the development of modern infrastructure and engineered sewer systems, waste was often discharged directly into rivers or other waterways. Natural processes such as dilution, bacterial decomposition, and sedimentation helped break down waste over time, but these methods could not keep pace with growing populations and industrial activity.

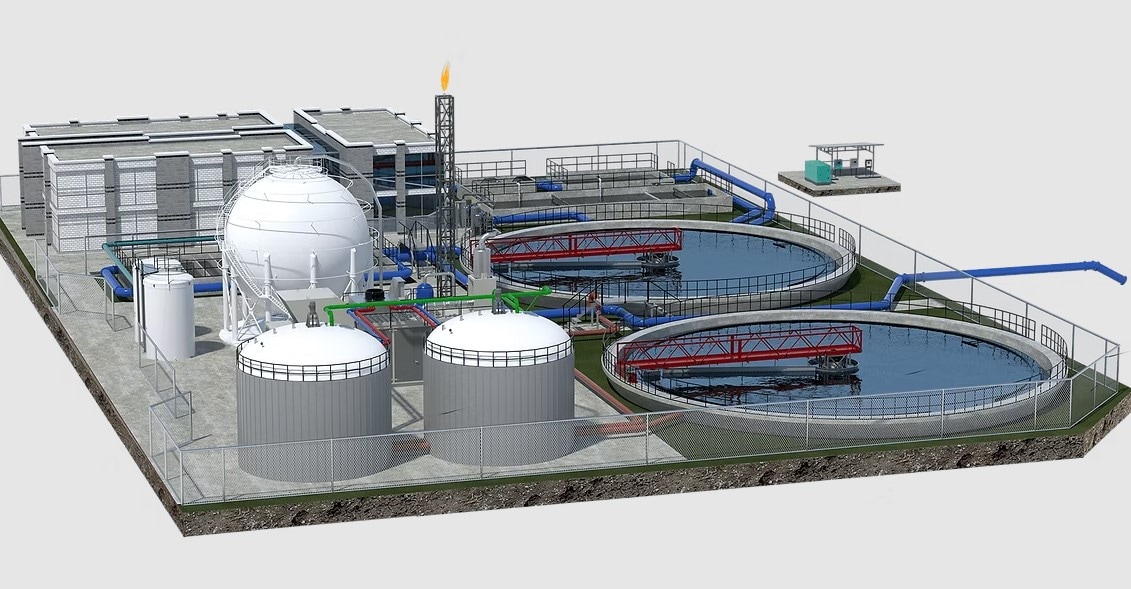

Modern wastewater treatment plants replicate and accelerate these same biological and chemical processes, but in a controlled, engineered environment. The goal is to speed up the natural purification cycle, efficiently removing solids, organic matter, and harmful microorganisms before releasing the treated water back into nature.

How the Wastewater Treatment Process Works

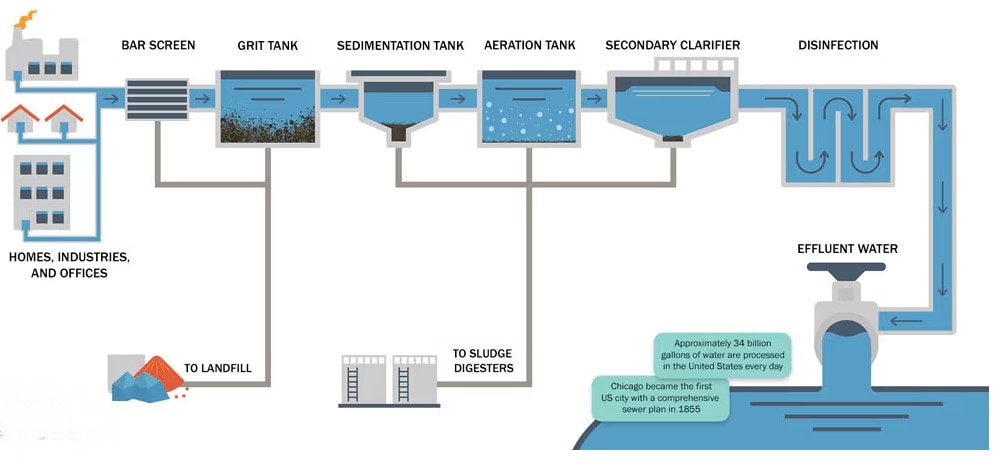

Step 1: Screening

When wastewater first enters a treatment facility, it passes through mechanical screens that capture large debris such as rags, plastic, and wood. Removing these objects early prevents damage to downstream pumps and pipes.

Step 2: Grit Removal

Next, the flow passes through a grit chamber, where heavier materials like sand, gravel, and small stones settle to the bottom. Grit removal is especially important in systems that handle stormwater, as runoff often carries soil and road debris into sewer lines. All screened and settled materials from the first two steps are typically transported to landfills for disposal.

Step 3: Primary Clarification (Sedimentation Tank)

In the primary clarifier, wastewater flow slows, allowing fine suspended solids to settle out by gravity. These solids form a sludge layer at the bottom of the tank, while lighter materials such as grease rise to the surface and are skimmed off.

Step 4: Aeration

The clarified water then enters an aeration tank, where air is pumped in to stimulate the growth of microorganisms. These microbes feed on the remaining organic matter, breaking it down into stable compounds. A small amount of activated sludge (a concentrated microbial culture) is added to accelerate this biological process.

Step 5: Secondary Clarification

After aeration, the mixture flows to a secondary clarifier, where the microbial biomass (activated sludge) settles out. A portion of this sludge is returned to the aeration tank to sustain the process, while the rest is sent to sludge digesters for further treatment.

The digestion stage takes about a month and relies on anaerobic bacteria—microorganisms that thrive without oxygen—to convert waste into methane gas and nutrient-rich biosolids. The methane can be captured and used to power the treatment plant, while biosolids serve as agricultural fertilizers that enrich soil and promote plant growth.

Step 6: Disinfection

The final treatment stage is disinfection, where the clarified water is mixed with chlorine or other disinfectants to eliminate harmful pathogens. When performed correctly, this process destroys over 99% of bacteria and viruses, ensuring that the treated water (effluent) can be safely released into rivers, lakes, or reused for non-potable applications.

Why Wastewater Treatment Matters

Modern wastewater treatment plays a vital role in environmental protection and public health. By removing contaminants and recovering valuable byproducts like energy and nutrients, treatment facilities help:

- Prevent pollution of waterways

- Support sustainable water reuse initiatives

- Protect aquatic life and ecosystems

- Conserve one of Earth’s most essential natural resources

As industrial and municipal water demand continues to grow, efficient wastewater management remains a cornerstone of sustainable development and regulatory compliance.

Innovative Solutions from

Monitoring Differential Pressure in Debris Filters

The Series-629C Wet/Wet Differential Pressure Transmitter provides a precise and reliable solution for monitoring pressure loss in filters, heat exchangers, and similar equipment. Designed for air, gas, and liquid measurement, the 629C achieves ±0.5% accuracy and offers both current and voltage output options. Its dual-sensor design and small internal volume deliver quick response and long-term stability, while the rugged NEMA 4X (IP66) enclosure ensures dependable performance in demanding wastewater environments.

Optional remote sensors simplify installation compared to traditional copper piping systems, eliminating the need for valve manifolds and reducing labor costs. For applications requiring local visibility, the 629C is available with an integral LCD display for easy on-site monitoring.

Level Monitoring in Holding and Settling Tanks

Throughout the treatment process, multiple holding and settling tanks are used to contain and separate produced water at various stages—from the initial collection after debris filtration to post-coagulation clarification. Maintaining proper liquid levels in these tanks is critical for ensuring consistent flow, preventing overfill, and optimizing residence time for settling or chemical treatment.

For reliable level measurement in these challenging environments, the Series-PBLT2 Submersible Level Transmitters delivers dependable performance in wastewater, sludge, and slurry applications. Its large 316 stainless steel diaphragm seal resists clogging and damage from floating solids, while an integrated surge protection system safeguards against power supply transients and lightning strikes.

For reliable level measurement in these challenging environments, the Series-PBLT2 Submersible Level Transmitters delivers dependable performance in wastewater, sludge, and slurry applications. Its large 316 stainless steel diaphragm seal resists clogging and damage from floating solids, while an integrated surge protection system safeguards against power supply transients and lightning strikes.

The PBLT2 measures hydrostatic pressure to determine liquid height and includes a rugged 270-pound tensile-strength cable with a built-in vent tube that automatically compensates for atmospheric pressure changes. A maintenance-free filter prevents particulates or moisture from entering the transducer, reducing service needs and extending product life. Together, these features make the PBLT2 an ideal choice for continuous, accurate level monitoring in harsh tank conditions.

For applications where non-contact measurement is preferred, the Series ULT Ultrasonic Level Transmitter offers a highly accurate and maintenance-free solution. Ideal for holding or settling tanks where buildup, foam, or corrosive conditions may challenge contact sensors, the ULT uses ultrasonic sound waves to determine liquid level without touching the media.

Capable of measuring up to 32.8 feet (10 meters) with a durable PVDF sensor, the Series ULT provides a 4-20 mA output for seamless integration with process control systems. Its non-contact design eliminates moving parts, preventing wear, jamming, and coating commonly encountered in wastewater applications. The transmitter’s mapping software narrows its sensing area to a precise 3-inch (76.2 mm) diameter column, ensuring accurate readings even in tanks with internal obstructions such as ladders, pipes, or mixers.

With an FM-approved explosion-proof housing and NEMA-rated construction, the Series ULT delivers reliable, long-term level measurement in harsh or hazardous environments. Together, the PBLT2 and ULT transmitters provide wastewater operators with both submersible and non-contact options to meet the demands of virtually any tank monitoring application.