Radon is a naturally occurring radioactive gas that can accumulate indoors and pose significant health risks if left unchecked. Regular radon testing is essential for ensuring safe indoor air quality, which is why “radon inspections” have become a standard part of home safety evaluations for buyers and sellers alike.

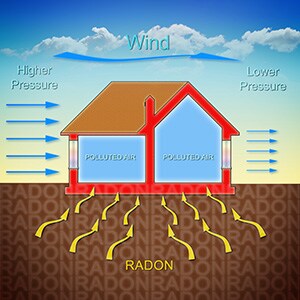

Radon is colorless, odorless, and tasteless, and forms when uranium in soil and rock breaks down into radium—and subsequently into radon. Because it originates underground, radon gas can enter homes through cracks in foundations, crawl spaces, sump pits, or even well water. Some areas have higher concentrations of radon due to local soil composition and geology, prompting mandatory testing in many regions.

Why is Radon Exposure a Concern?

When radon gas decays, it emits radioactive particles that can become trapped in your lungs when inhaled. Over time, exposure to these particles increases the risk of lung cancer. According to the U.S. Environmental Protection Agency (EPA), radon exposure contributes to approximately 21,000 lung cancer deaths in the United States each year, making it the second leading cause of lung cancer after smoking.

Because radon moves from areas of higher concentration (the soil) into areas of lower concentration (indoor air), basements and lower levels of buildings tend to be most affected. The process is similar to how heat flows from a warm space to a cooler one, driven by a natural pressure gradient.

How Radon Mitigation Systems Work

If a radon test detects levels above the EPA’s action threshold (4 pCi/L), a radon mitigation system is typically installed. The most common design is a sub-slab depressurization system. This method uses a combination of PVC vent piping and a radon fan to draw the gas from beneath the building’s foundation and discharge it safely above the roofline, away from windows or air intakes.

The principle is simple but effective: by creating negative pressure beneath the slab, radon is prevented from entering the living space. These fans are often located in basements, attics, or outdoors to minimize noise and provide continuous operation.

However, because the fan and piping are usually hidden from view, it can be difficult for homeowners or facility managers to know whether the system is operating properly.

Why Continuous Monitoring Matters

Even if initial testing confirms that radon levels have dropped after installation of a mitigation system, ongoing verification is just as critical. A failed fan, blocked vent, or damaged pipe can allow radon levels to rise again without immediate detection.

To ensure consistent performance, pressure and airflow monitoring devices are commonly installed on the system’s vent piping or near the suction point beneath the slab. These instruments help verify that a negative pressure field is being maintained.

Monitoring can be as simple as a visual gauge or as advanced as a digital pressure transmitter tied into a building automation or data logging system. The goal is to confirm that air is being pulled effectively through the mitigation piping, indicating that the fan is functioning as intended.

Innovative Solutions from

Model DAFA Air Flow Indicator & Alarm for Radon Mitigation

The

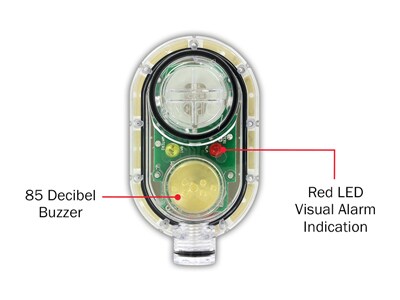

Model DAFA Air Flow Indicator and Alarm was designed with the homeowner in mind, providing a simple and effective way to ensure that radon mitigation systems are operating properly. Traditional mitigation setups often rely on a U-tube style manometer mounted in a basement or garage. These require homeowners to visually check for pressure differences to confirm that the fan is running. Because these gauges are not easily visible or frequently inspected, potential fan failures can go unnoticed for long periods of time.

The DAFA addresses this issue by offering both visual and audible alerts that immediately notify users of a system fault. The unit features a thin, field-trimmable vane that detects airflow within 3-inch or 4-inch pipes. When airflow drops below normal levels, an 85 dB buzzer sounds and a bright red LED flashes to indicate a “no flow” condition. A yellow LED provides a clear low-battery warning to ensure continued reliability.

Battery operation allows the DAFA to be installed anywhere without requiring a hardwired power source, and its typical five-year battery life keeps maintenance needs minimal. This makes it an ideal upgrade or replacement for traditional manometers, providing continuous, automatic system verification for radon mitigation systems.

Key Features:

- Monitors airflow using a thin, trimmable vane for 3" and 4" pipes

- Audible and visual alarms for low or no flow conditions

- 85 dB buzzer and bright LED alerts

- Battery-powered design with up to five years of life

- Low battery indication for dependable operation

Connect with a DwyerOmega Expert Today!