Mineral Insulated (MI) cable is a highly durable, heat-resistant wiring solution used in demanding environments where conventional cables would otherwise fail. These cables consist of metal conductors encased in a densely packed magnesium oxide (MgO) insulation and protected by a robust metallic sheath, making MI cable an ideal choice for high-temperature, high-voltage, corrosive, and/or hazardous environments.

Construction and Materials

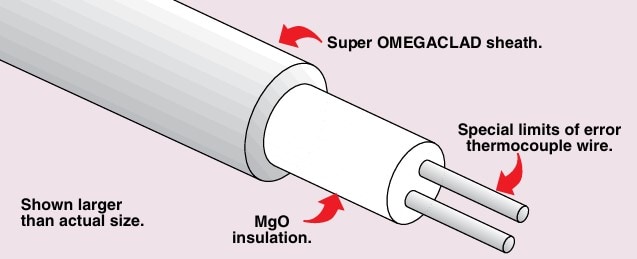

MI cable is engineered for durability and reliability in extreme conditions. It consists of one or more solid metal conductors (usually copper or nickel alloy) embedded in compressed magnesium oxide (MgO), a highly effective insulator that also offers excellent thermal conductivity. This insulated core is encased in a seamless metallic sheath, typically made from stainless steel, Inconel®, copper, or DwyerOmega's superior Super OMEGACLAD® XL—excellent for long term stability at high temperatures. Sheath material should be chosen based on the specific needs of any given application.

Each component of MI cable serves a specific function:

- Conductors: Transmit electrical signals or power. Available in different sizes and configurations based on current load and application type

- Magnesium Oxide Insulation: A dry, inorganic powder that resists high temperatures and electrical leakage. MgO enables MI cable to function reliably in extreme environments

- Metallic Sheath: Acts as a protective armor against moisture, chemicals, physical damage, and electromagnetic interference

Advantages of MI Cable

Mineral insulated cable offers several key benefits that make it the preferred choice in harsh or safety-critical environments:

-

High Temperature Resistance

-

MI cable can withstand continuous exposure to temperatures exceeding 540 °C (1000 °F), making it ideal for furnaces, kilns, and heat treatment systems.

Fireproof and Flame Retardant

-

Because all components are inorganic and non-combustible, MI cable continues to operate during and after exposure to fire. This makes it essential for fire detection systems, emergency circuits, and building safety compliance.

Excellent Electrical Insulation

-

The magnesium oxide insulation resists moisture and degradation over time, providing stable performance and low leakage even in high-humidity or high-voltage environments.

Mechanical and Chemical Durability

-

The metallic sheath protects against impact, vibration, corrosion, and electromagnetic interference—extending cable lifespan in demanding industrial settings.

Compact and Long-Lasting

-

MI cable has a small diameter relative to its performance, allowing for easy installation in tight spaces. With no organic materials to age or decay, it offers a significantly longer service life than conventional wiring.

High-Temperature Sheathing: Super OMEGACLAD® XL

Super OMEGACLAD® XL is a specialized sheath material used in mineral-insulated thermocouple wire designed for prolonged exposure to extreme temperatures. This NickelChrome-based alloy provides exceptional oxidation resistance, enabling stable operation in high-temperature environments up to 1150 °C (2102 °F) during continuous use, with tolerance for even higher temperatures under short-term conditions.

One of its key advantages is the formation of a tenacious and protective high-temperature film that shields the thermocouple without compromising the stability of the base metal alloys. This allows for more accurate temperature readings over extended periods compared to other sheath materials.

Super OMEGACLAD® XL also performs reliably in chemically aggressive conditions. It resists corrosion in chlorine-contaminated oxidizing environments and ammonia/nitride-rich atmospheres at temperatures above 980 °C (1800 °F)—precisely where its protective film begins to form and provide enhanced defense.

Connect with a DwyerOmega Expert Today!