A thermocouple is a thermoelectric device used to measure temperature. It works on the principle that when two dissimilar metals are joined at one end and exposed to a temperature difference, they produce a small voltage that can be correlated to temperature.

How Does a Thermocouple Work?

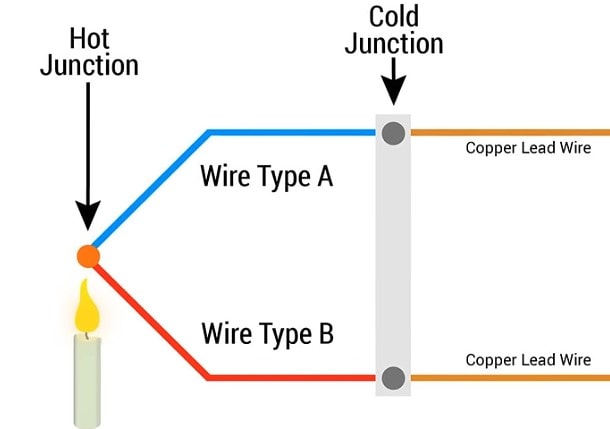

A typical thermocouple consists of two dissimilar metal wires joined together at both ends. One junction is placed in the medium or on the surface that is being measured—this is known as the hot junction. The other end, called the cold junction, is connected to a thermocouple-compatible device, such as a meter, a controller, or a transmitter, that remains at a constant, known temperature.

When the hot junction experiences a temperature change, the heat causes the electrons within each metal wire to move. Because the two wires that make up any given thermocouple are made from different alloys, their electrons move at different rates. This creates a measurable millivolt signal between the two conductors. The wire whose electrons move more freely develops a negative charge at the cold junction, while the other becomes the positive lead.

From this difference in potential, the device calculates temperature using a formula that converts the millivolt output into a temperature value.

Thermocouple Types and Ranges

Each thermocouple alloy combination (defined by the materials used) determines its temperature range and sensitivity. These combinations are standardized and represented by letter designations. The most common are the base metal thermocouples:

- J J Type J (Iron-Constantan)

- K K Type K (Chromel-Alumel)

- T T Type T (Copper-Constantan)

- E E Type E (Chromel-Constantan)

- N N Type N (Nicrosil-Nisil)

* Left badge represents ANSI color code; right badge represents IEC color code.

Among these, Type K Thermocouples are the most widely used due to their low cost, versatility, and wide temperature range, making them ideal for general-purpose temperature measurement.

Thermocouples in Action: Common Thermocouple Applications

Rugged, cost-effective, and reliable, thermocouples are widely used throughout numerous industries and applications for temperature measurement and process control. Their ability to withstand harsh environments, respond quickly to temperature changes, and interface easily with controllers, transmitters, and data loggers makes them a universal sensing solution.

HVAC Systems

Thermocouples are used throughout HVAC systems. They help maintain consistent environmental conditions, optimize system efficiency, and protect equipment from overheating. Common applications include supply and return air temperatures, boiler and chiller monitoring, and duct temperature profiling in both commercial and industrial facilities.

Industrial Ovens and Furnaces

In high-temperature applications such as metal heat treatment, ceramics, and glass manufacturing, thermocouples provide accurate and repeatable temperature feedback for process control. Type K and Type N thermocouples are especially common due to their high-temperature stability and resistance to oxidation. Their readings ensure that heating cycles remain within precise temperature tolerances, critical for achieving material strength and consistency.

Food & Beverage Processing

Accurate temperature measurement is essential in ensuring product safety and quality during cooking, pasteurization, freezing, and storage. Thermocouples are ideal for these applications because they offer fast response times and can be fabricated in sanitary probe configurations for compliance with FDA and HACCP standards. They are also used in ovens, fryers, and packaging systems to verify that products remain within specified temperature limits.

Injection Modling

Thermocouples are integral to the plastic injection molding process, where they monitor barrel, nozzle, and mold temperatures to maintain material quality and uniform part production. Real-time feedback allows controllers to adjust heater bands and coolant flow automatically, preventing defects such as warping or incomplete fills.