What are Strain Gauges? Strain gauges convert mechanical deformation into measurable resistance changes through the piezoresistive effect. Small resistance shifts are detected using a Wheatstone bridge with amplification and temperature compensation. Common types include linear, diaphragm, rosette, torsion, and dual-parallel gauges—each suited to specific stress directions and materials. Used widely in structural testing, load and pressure measurement, and industrial condition monitoring, strain gauges provide precise data essential for safety, performance, and predictive maintenance across engineering applications.

Tagged as:Blog, Get Curious

Read More

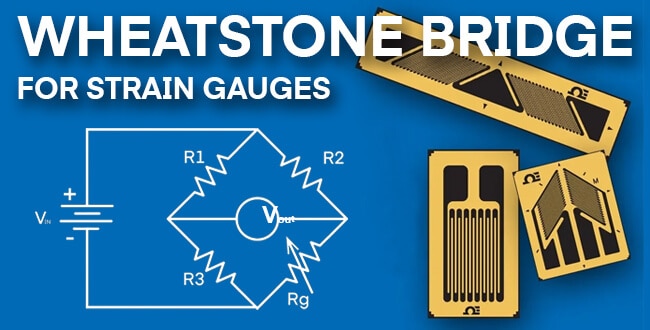

What is a Wheatstone Bridge? In order to measure strain with a bonded resistance strain gauge, it must be connected to an electric circuit that is capable of measuring the minute changes in resistance corresponding to strain.

Tagged as:Technical Learning, Get Curious

Read More

Strain Gauge When external forces are applied to a stationary object, stress and strain are the result.

Tagged as:Technical Learning, Get Curious

Read More

Strain Gage Technical Data The most universal measuring device for the electrical measurement of mechanical quantities is the strain gage.

Tagged as:Technical Learning, Get Curious

Read More

Optimizing Strain Gage Performance for Inhomogeneous Materials How to use strain gages and optimize their performance while working with inhomogeneous materials

Tagged as:Technical Learning, Get Going

Read More

Sensor Theory of Operation Omega is a reliable source for pressure transducers and load cells that provide high quality data in a myriad of processes.

Tagged as:Technical Learning, Get Curious

Read More

Strain Gage Application Requires Quality Control Surface Preparation and Application Steps OMEGA Engineering offers four types of strain gages: The Karma Grid or K-Series, Precision Strain Gages, Pre-Wired Gages, Transducer Quality.

Tagged as:Technical Learning, Get Going

Read More