When it comes to your application, as any process engineer can tell you, accuracy is everything. However, even the best designed instruments can give misleading results if they are not read correctly. One of the most common culprits of this is parallax error, a visual distortion that occurs when you view an analog gauge or dial from an angle instead of head on (think of when you’re looking at a car’s fuel gauge from the passenger seat). This small (and seemingly innocent) mistake can lead to big consequences, from misjudging pressure levels in an HVAC system to misreading flow measurements in a production line. Understanding what parallax error is, why it occurs, and how to avoid it will improve measurement accuracy and reliability for your application.

What is Parallax Error?

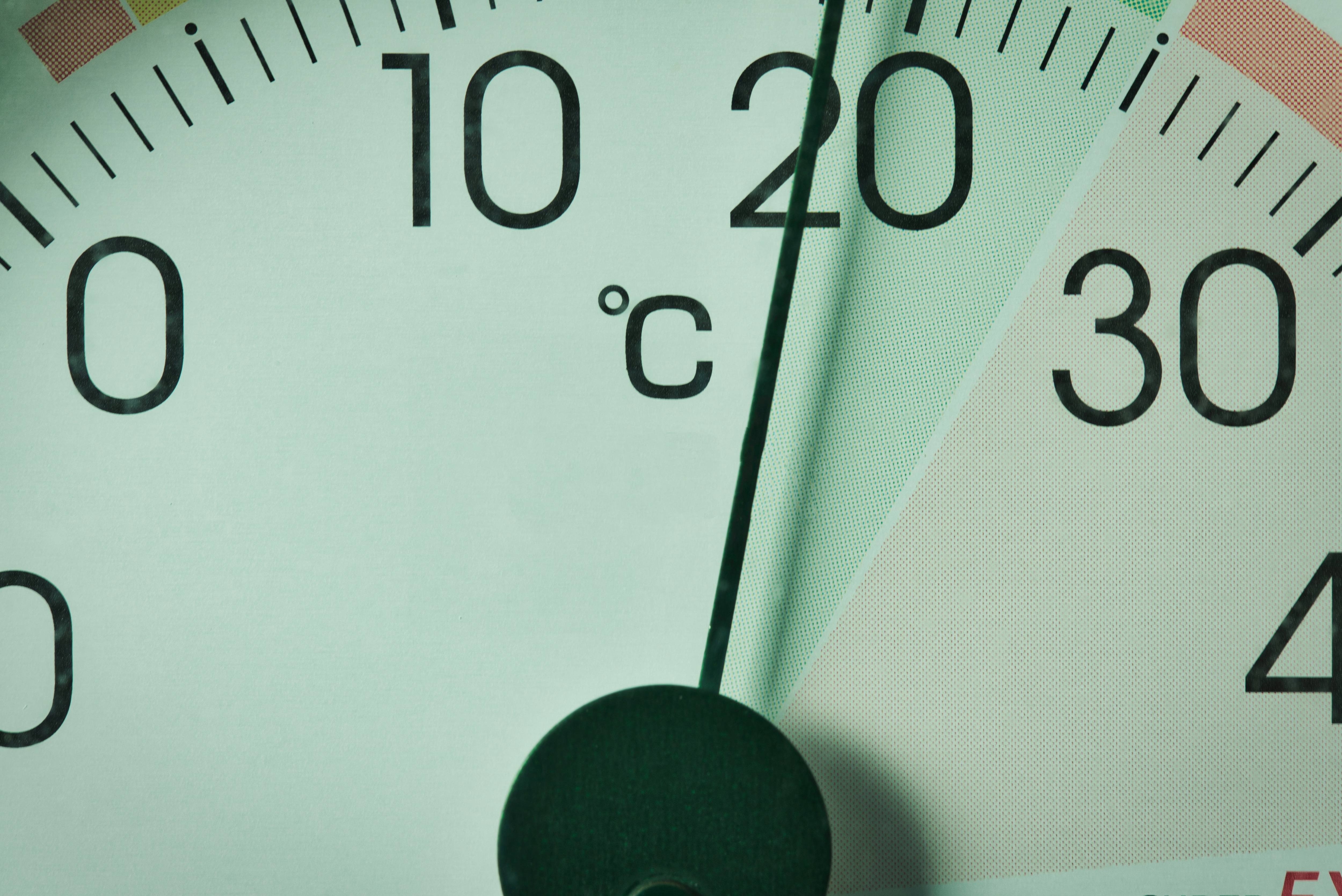

Parallax error occurs when a measurement is read from an angle rather than straight on, causing the pointer (needle) of a dial instrument to appear at a different position relative to the scale.

In metrology terms, parallax error is an observational error rather than an error inherent to the instrument. The device may be calibrated correctly, but improper viewing introduces an inaccuracy.

When Might You Encounter Parallax Error?

Instruments Prone to Parallax Error

-

• Pressure Gauges

Common in HVAC, process controls, and hydraulics -

• Dial Thermometers

Used in boilers, ovens, and refrigeration systems - • Flow Meters

- • Analog Voltmeters

Real-World Example

Parallax error can be subtle but significant in practice. Consider a technician monitoring boiler pressure with a dial gauge. Viewed from the side, the pointer may appear to indicate 95 psi. When viewed directly from the front, however, the correct reading is 100 psi. This 5% error could lead to unnecessary adjustments, operational inefficiencies, or even unsafe conditions if not corrected.Industry Applications Where Parallax Error Matters

- HVAC Systems: Incorrect gauge readings may lead to improper refrigerant charging or airflow adjustments

- Process Control: In chemical plants or food processing, even small deviations in temperature or pressure affect product quality

- Power Generation & Utilities: Students in physics or engineering labs learn the importance of proper measurement techniques by observing parallax firsthand

How to Avoid Parallax Error

Parallax error can be eliminated through proper technique and the selection of appropriate instrumentation. The most direct method is to read instruments straight-on, ensuring that the observer’s line of sight is perpendicular to the pointer and scale. This removes the angular distortion that causes a reading to appear shifted.

Another approach is to use gauges specifically designed to reduce parallax error. Certain high-quality analog instruments incorporate a mirrored band or overlay behind the pointer; alignment of the pointer with its reflection confirms that the gauge is being viewed correctly.

Installation practices also influence accuracy. Mounting gauges at eye level allows for direct readings without requiring technicians to view them from above, below, or at an angle, minimizing the likelihood of observational error during routine checks.

Finally, personnel training is essential. Operators and technicians should understand the source of parallax error and be instructed on correct observation techniques.

Innovative Solutions from DwyerOmega

Avoiding parallax error often comes down to choosing the right instrumentation. DwyerOmega gauges and transmitters combine accuracy, durability, and ease of use.

Series 2000 Magnehelic® Differential Pressure Gauge

The Series 2000 Magnehelic® is one of the most trusted differential pressure gauges in the industry, engineered for reliable performance in HVAC, cleanroom, and process control environments.

- Easy-to-read analog display: The undistorted plastic face and clear full-scale dial allow technicians to make quick, accurate assessments with minimal risk of misinterpretation

- Rugged design: A die-cast aluminum housing with an IP67 seal resists dust, moisture, and demanding industrial conditions

- Precision mechanism: Its patented diaphragm and magnetic movement system ensure stable, responsive readings for low differential air and non-corrosive gas pressures

- Versatile mounting: The flush-mount bezel makes installation simple across panels and system layouts

- No power required: Operates mechanically for maintenance-free reliability

Trusted worldwide, the Series 2000 is the go-to solution for monitoring filter status, air handling performance, and cleanroom conditions. Its design minimizes observational error while providing dependable readings where accuracy matters most.

Connect with a DwyerOmega Expert Today!