An air handling unit (AHU) is a central component of a building’s HVAC system. Its primary job is to circulate air, most commonly in a commercial facility or industrial space. By working with heating and cooling equipment, the AHU distributes conditioned air and helps maintain safe, comfortable, and healthy indoor environments.

Air handling units are found everywhere: walk into an office, a school, a hospital, a sports arena, and you are going to find that an AHU is operating behind the scenes, regulating air movement and managing temperature and humidity levels. To perform these core functions, modern AHUs rely on sensors and transmitters to monitor air quality, detect faults, improve energy efficiency, and allow for effective preventative maintenance.

Key Components of an Air Handling Unit

An AHU is made up of several integrated parts, including (but not limited to):

Fan or Blower Motor

- The blower forces air through the connected ductwork

- Supply air is delivered into occupied rooms

- Return air is pulled back into the system for reconditioning or exhaust

Evaporator Coil

The coil either removes heat from the air during cooling or adds heat when paired with heating equipment. As air passes across the coil, its temperature is adjusted before being recirculated throughout the building.

Air Filter

The filter captures airborne particles such as dust, pollen, mold, and bacteria. High-quality filtration is essential for maintaining indoor air quality and protecting both occupants and HVAC equipment.

Additional Features Found in AHUs

Beyond the core components, many air handlers include optional accessories that further improve environmental control. Examples include:

- Humidifiers that maintain stable indoor humidity

- Air purifiers that reduce contaminants and odors

- Sensors and transmitters that track temperature, humidity, pressure, airflow, and filter status

These devices help ensure the AHU is functioning correctly, support preventive maintenance programs, and contribute to energy savings by allowing the system to operate more efficiently.

What is a Rooftop Unit?

A rooftop unit (RTU) is a self-contained HVAC system commonly installed on the roof of a commercial building. Unlike an AHU, which works alongside separate heating or cooling equipment, an RTU packages heating, cooling, filtration, and airflow components into one cabinet. This all-in-one design saves indoor space and simplifies installation, making RTUs popular in retail stores, offices, schools, and warehouses.

Typical RTU components include a supply fan, return fan, filters, heating elements, cooling equipment, and outdoor aid dampers that modulate ventilation. Because the unit is packaged, maintenance is straightforward, and system upgrades can be handled with minimal disruption.

AHU vs RTU: Key Differences

While both AHUs and RTUs move and condition air, they are designed for different types of HVAC systems and building needs.

Air Handling Units

- Part of a larger, centralized HVAC system

- Require separate heating or cooling equipment such as chillers, boilers, or heat pumps

- Offer greater flexibility for airflow control, humidity management, and filtration levels

- Commonly used in hospitals, laboratories, universities, and industrial buildings

Rooftop Units

- Packaged systems with heating, cooling, and air movement components in one enclosure

- Easier to install and maintain due to their self-contained design

- Best suited for small to mid-sized commercial buildings where space and budget are key considerations

- Common in retail stores, restaurants, offices, and warehouses

Innovative Solutions from

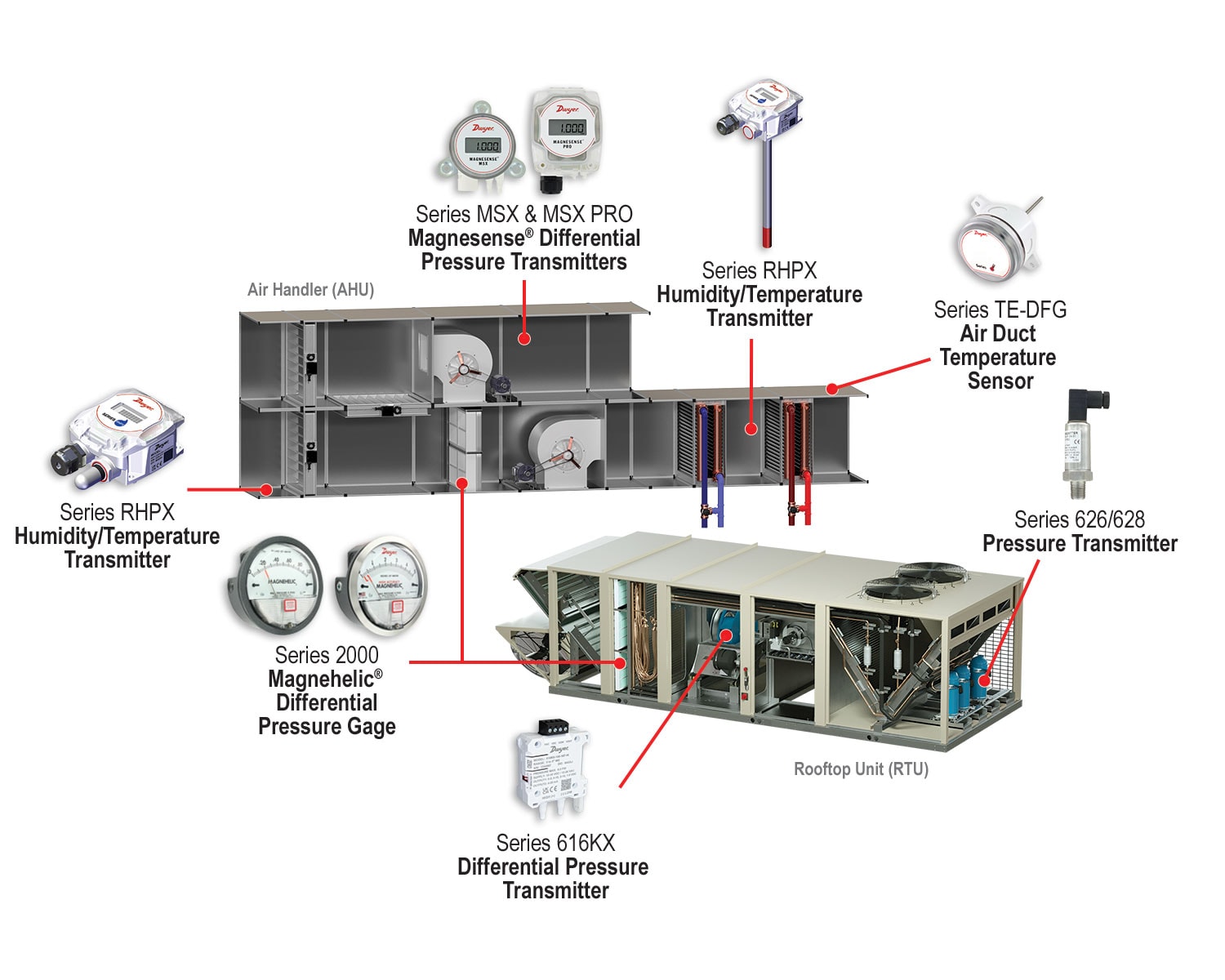

Series MSX Pro Differential Pressure Transmitter

The Series MSX Pro Differential Pressure Transmitter provides accurate, stable pressure measurement for high performance HVAC applications. Its flip-lid housing allows fast access to wiring during installation, while the tamper-resistant cover helps protect settings in commercial and industrial environments.

Each MSX Pro Magnesense® Differential Pressure Transmitter offers 32 selectable pressure ranges in pascals, millimeters of water column, and inches of water column. Users can choose unidirectional or bidirectional modes and select either a linear pressure output or a velocity output with square root extraction. Additional parameters allow the device to calculate airflow, making it a versatile option for AHUs and VAV systems.

Dual voltage and milliamp outputs support both control and signal verification needs. A NIST calibration option is available for projects that require documented accuracy.

Common Applications

- Filter monitoring in air handling units

- Building and room pressure control in clean rooms and critical spaces

- Duct static pressure measurement

- Air velocity and flow in VAV systems

Series RHPX Humidity & Temperature Transmitter

The Series RHPX Humidity and Temperature Transmitter provides accurate, stable measurement for commercial HVAC and building automation applications. By integrating multiple on-board sensors into a single device, the RHPX helps reduce installation time, wiring complexity, and overall system cost while supporting precise environmental control.

Available in 2 % or 3 % RH accuracy models and built with capacitance polymer humidity sensors, the Series RHPX delivers long-term reliability with minimal maintenance. An optional two-line LCD allows for quick local verification during installation and commissioning.

Designed for installation flexibility, the RHPX features UL 2043 compliance for plenum spaces, UV-rated outdoor enclosures, and installer-friendly features such as a removable terminal block, attached lid, and integrated cable management. Optional outputs including dew point, absolute humidity, and enthalpy make it suitable for advanced HVAC control strategies.

Common Applications

- Air economizers

- Outdoor humidity and temperature reference

- Pool room humidity monitoring

- Commercial HVAC systems

- Clean rooms

- Museums

- Data centers

Series TE Duct and Immersion Temperature Sensor

Installation is streamlined through several practical design features. Duct models offer flanged mounting options, while housing versions include multiple conduit knockouts for flexible wiring access. The 1/4 turn lid is secured with an attached chain to prevent accidental dropping during installation. For variable air volume systems, an 8 foot plenum rated cable option with flying leads is available to simplify routing within ductwork.

Thermowells are recommended for immersion applications but are not required. Lookup tables are available for models that use resistive thermistors or RTD outputs.

Common Applications

- Building automation systems

- VAV temperature measurement

- Chiller and boiler loop monitoring

- AHU temperature sensing

Series 626 and 628 Accurate Industrial Pressure Transmitters

Series 626 and Series 628 Industrial Pressure Transmitters deliver accurate, reliable pressure measurement for industrial, pneumatic, hydraulic, and HVAC applications. Each transmitter converts pressure into a stable electrical signal, supporting efficient system control and monitoring without the need for frequent recalibration.

Both models are designed for harsh environments and feature a rugged NEMA 4X (IP66) enclosure that protects against dust, moisture, and corrosion. The Series 626 provides high accuracy at ± 0.25 % of full scale, while the Series 628 offers a cost-effective alternative with ± 1.0 % accuracy. A wide selection of pressure ranges and electrical output options allows easy integration into new or existing systems.

Common Applications

- Process control systems

- HVAC and building systems

- Pneumatic and hydraulic circuits

- OEM equipment and machinery

Series 616KX Differential Pressure Transmitter

The Series 616KX Differential Pressure Transmitter is a compact, cost-effective solution designed for HVAC and OEM applications where space, simplicity, and flexibility are critical. As Dwyer’s smallest differential pressure transmitter, the 616KX delivers reliable performance while making installation and servicing faster and easier.

One-Touch® Digital Push-Button Calibration allows installers to quickly reset zero and span directly at the device, reducing setup time and simplifying recalibration over the service life. Field-selectable current or voltage outputs provide added flexibility for integration with a wide range of control systems.

The molded housing supports multiple imperial and metric tubing sizes through stepped barbed fittings, with optional threaded connections available for added versatility. Combined with a wide operating temperature range and low power consumption, the Series 616KX is well suited for continuous monitoring in demanding HVAC environments. Optional NIST-traceable calibration is available through the product configurator.

Common Applications

- Air handlers

- Duct static pressure

- Variable air volume systems

- Filter monitoring

Series 2000 Magnehelic® Differential Pressure Gage

The Series 2000 Magnehelic® Differential Pressure Gage provides simple, reliable monitoring of low air and gas pressures without requiring any power source. Its precision diaphragm and magnetic movement system produce fast, consistent readings, making it a dependable choice for HVAC and process applications that need clear, at-a-glance pressure indication.

The gauge is built with a rugged die-cast aluminum housing and sealed to an IP67 rating for protection against dust and moisture. Its distortion-free clear face ensures visibility from multiple angles, and the bezel allows easy flush mounting in panels. With durable components and built-in overpressure protection, the Magnehelic® Differential Pressure Gage delivers long service life with minimal maintenance.

Common Applications

- Air handling units and duct systems

- Filter loading indication

- Clean rooms and controlled environments

- General industrial process monitoring