Variable area flow meters measure flow rate by allowing a fluid to pass through a tapered tube that raises a float to a height proportional to the flow velocity. These instruments are factory-calibrated for a specific medium under standard reference conditions. For most models, those standards are air (for gas applications) and water (for liquid applications) at 70 °F and 14.7 PSIA (0 PSIG).

However, when a flow meter operates under conditions that differ from these reference standards, its indicated flow will not represent the true flow rate. To ensure accuracy, engineers must apply corrections for pressure, temperature, and specific gravity.

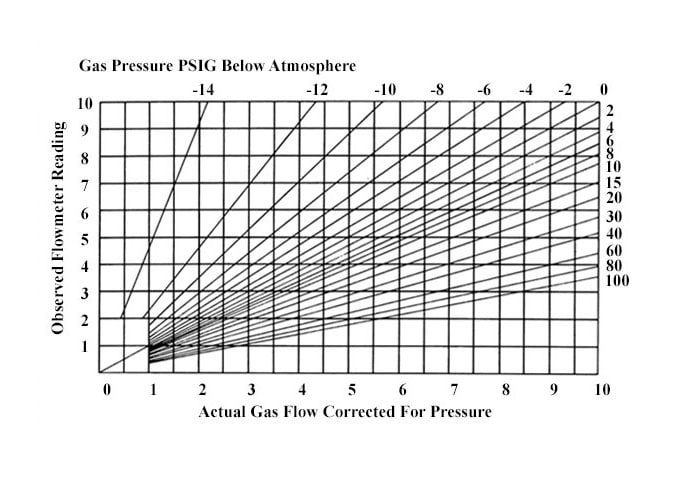

Gas Flow Corrections for Pressure and Temperature

Gases are highly compressible, so their density varies significantly with both pressure and temperature.

The reading observed on the flow meter is the actual flow rate (Q₁), while the corrected value—adjusted to standard conditions—is the standard flow rate (Q₂).

To correct the actual flow to standard flow conditions, the following equation can be used:

Where:

- Q1 = Actual flow rate (indicated by the meter)

- Q2 = Corrected (standard) flow rate

- P1 = Actual pressure (PSIA)

- P2 = Standard pressure (14.7 PSIA)

- T1 = Actual temperature (°R = °F + 460)

- T2 = Standard temperature (530 °R, equivalent to 70 °F)

This formula accounts for how changes in gas density affect the float’s position inside the meter. For example, a higher operating pressure increases gas density, causing the float to rise less for the same volumetric flow rate. Applying this correction yields a true, standard-condition flow rate.

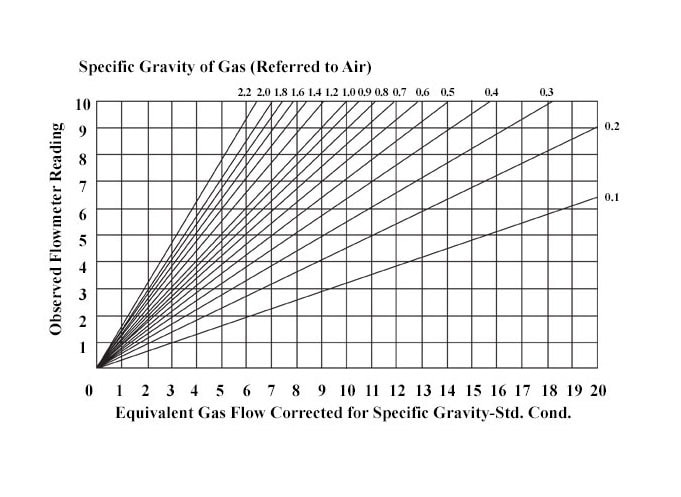

Gas Flow Corrections for Different Media

When using a variable area flow meter calibrated for air to measure a different gas, an additional correction is required to account for differences in specific gravity (S.G.).

The following equation is used:

Where:

- Q1 = Flow rate of the gas indicated on the meter

- Q2 = Corrected flow rate for the gas being used

- S.G. = Specific gravity of the gas (relative to air, where air = 1.0)

For example, if the meter is calibrated for air but used with carbon dioxide (S.G. ≈ 1.52), the indicated flow will read higher than the actual rate, and this correction ensures proper adjustment.

Innovative Solutions from

Series VF Visi-Float® Flow meters

For precise, repeatable gas or liquid measurement under standard or corrected conditions, the Series VF Visi-Float® Flow meters provide a reliable and visually clear solution. Each unit is precision machined from a solid acrylic block, allowing a complete visual inspection of flow while maintaining excellent durability and clarity.

The white background and high-contrast float design ensure accurate readings, while the tapered bore delivers smooth float travel and exceptional repeatability. Available in 2-inch and 4-inch scales with optional precision metering valves, the Series VF is ideal for air, water, or process gas applications where variable area flow measurement and correction may be required.

Additional Features:

- Measurement pressure type: Gauge

- Process connection: 1/8 in NPT female

- Proof pressure: Up to 100 psi

- Orientation: Vertical installation

- NIST calibration available in the product configurator

Common Applications:

- Medical and laboratory systems

- Air samplers

- Gas analyzers

- Pollution monitors

- Chemical injectors

- Cabinet purging systems

Series VA Variable Area Flow Meters for Gas & Liquid

The Series VA Variable Area Glass Flow meters deliver precision gas or liquid measurement with a universal millimeter scale and included correlation charts for both air and water. Each unit is equipped with a standard 6-turn needle valve that allows for smooth and accurate flow control, eliminating the need for a separate valve and reducing installation costs.

A permanently fused ceramic scale with a vertical locator line minimizes parallax error and eye strain, helping operators take faster, more reliable readings. The flow meter can be panel-mounted or easily converted to a self-standing bench setup using an optional acrylic tripod base.

Key Features:

- Permanently fused ceramic scale for reduced parallax and operator fatigue

- 6-turn needle valve for precise flow control

- Optional tripod base for standalone bench mounting

- Factory-supplied correlation charts for air and water

- High-precision metering valves available for ultra-low flow rates

- Calibration data unique to each unit (certificate available under accessories)

Common Applications:

- Gas or liquid metering

- Chemical processing

- Semiconductor systems

- Water and air pollution analysis

- Laboratory systems

Series RM Rate-Master® Flow Meters

The Series RM Rate-Master® Flow Meters are direct-reading, precision-engineered flow meters designed for accurate gas and liquid measurement across a range of industrial and laboratory applications. Available in 2-inch, 5-inch, and 10-inch scales, these flow meters can be either panel-mounted or surface-mounted and are built for long service life with a durable, shatter-proof polycarbonate body.

A stainless steel backbone absorbs piping torque to prevent installation damage, while precision injection molding around a tapered pin ensures consistent accuracy and repeatability. Each unit features direct reading scales, eliminating conversion calculations and simplifying setup. Optional NIST calibration provides added traceability for regulated environments.

Key Features:

- Direct reading scales eliminate the need for flow conversions

- Stainless steel backbone absorbs piping torque and protects the meter

- Shatter-proof polycarbonate body for long-term durability

- High repeatability from precision-molded tapered pin design

- Interchangeable body design within each scale size for easy cleaning and maintenance

- NIST calibration available through product configurator

Common Applications:

- Medical equipment

- Air samplers

- Gas analyzers

- Pollution monitors

- Chemical injectors

- Cabinet purging systems