Using Thermocouple-Grade or Extension-Grade Wire helps ensure maximum temperature measurement accuracy - minimizing errors related to alloy composition or calibration mismatch.

Explore DwyerOmega's Selection

Using Thermocouple-Grade or Extension-Grade Wire helps ensure maximum temperature measurement accuracy - minimizing errors related to alloy composition or calibration mismatch.

Explore DwyerOmega's Selection

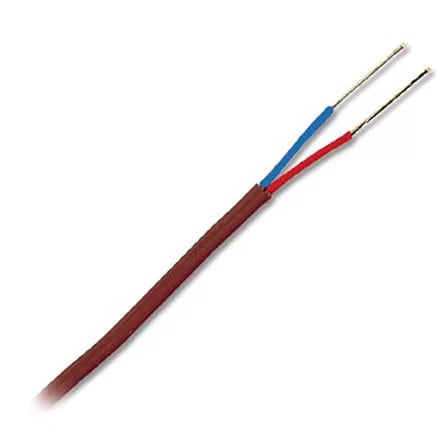

When using thermocouple sensors, the thermocouple wire used to carry the signal is just as important as the thermocouple sensor itself. Thermocouple wire is made from the same allow materials as the thermocouple sensor, and its primary role is to extend the thermocouple circuit from sensing junction (“hot junction”) to the measurement instrument (“cold junction”) without introducing additional errors. Thermocouple wire is made from the same allow materials as the thermocouple sensor, and its primary role is to extend the thermocouple circuit from sensing junction (“hot junction”) to the measurement instrument (“cold junction”) without introducing additional errors.

Why is Thermocouple Wire Important?

Thermocouples work by joining two dissimilar metal wires at one end (the hot junction), which produces a voltage as it experiences temperature changes. This voltage, measured at the cold junction, corresponds to the temperature at the sensing point. The specific combination of metals defines the thermocouple calibration type – such as Type K, J, T, or N. Each type has unique thermoelectric properties that affect accuracy, temperature range, and environmental suitability.

Unlike standard copper or general-purpose wire, the material characteristics of thermocouple wire must match precisely with the thermoelectric properties of the thermocouple sensor calibration type being used. This is the case because thermocouple wire relies on a predictable voltage change between the two metals to correlate back to a temperature measurement. Matching characteristics precisely ensures the integrity of temperature measurements across the entire system, as any variation in the wire material can lead to errors in the temperature measurement.

Comparing (Some) Thermocouple Wire Types

| ANSI Code | IEC Code | Maximum Useful Temperature Range | Standard Limits of Error (Above 32 °F/ 0 °C) | Special Limits of Error (Above 32 °F/ 0 °C) | Alloy Combination: + Lead | Alloy Combination: - Lead | Comments Environment Bare Wire | |

|---|---|---|---|---|---|---|---|---|

| J | J | -40 °C to 750 °C | High | Low | Iron / Constantan | Plastics processing, older equipment | Buy Now | |

| K | K | -200 °C to 1,260 °C | Medium | High | Chromel / Alumel | Industrial furnaces, engines, kilns | Buy Now | |

| T | T | -200 °C to 350 °C | High | Excellent (moisture) | Copper / Constantan | Cryogenics, food processing | Buy Now | |

| E | E | Buy Now | ||||||

| N | N | -200 °C to 1,300 °C | Medium | Excellent | Nicrosil / Nisil | High-temp precision, harsh environments | Buy Now |