Thermistors are semiconductor devices designed to exhibit a large change in resistance proportionate to a small change in temperature. The term thermistor comes from “thermally sensitive resistor,” reflecting how these sensors function: their electrical resistance shifts in direct response to temperature. Because even minor temperature changes cause significant variations in resistance, thermistors provide exceptional sensitivity and resolution across industrial, commercial, and scientific applications.

Standard thermistors are accurate to within about ± 1 °C, while specialized models can achieve even tighter tolerances. Beyond accuracy, thermistors are also valued for their fast response time—typically defined by a “time constant,” or the number of seconds it takes the sensor to register about 63 % of a sudden temperature change. These characteristics make thermistors a reliable, cost-effective choice for monitoring and controlling temperature in a wide range of environments.

How Do Thermistors Work?

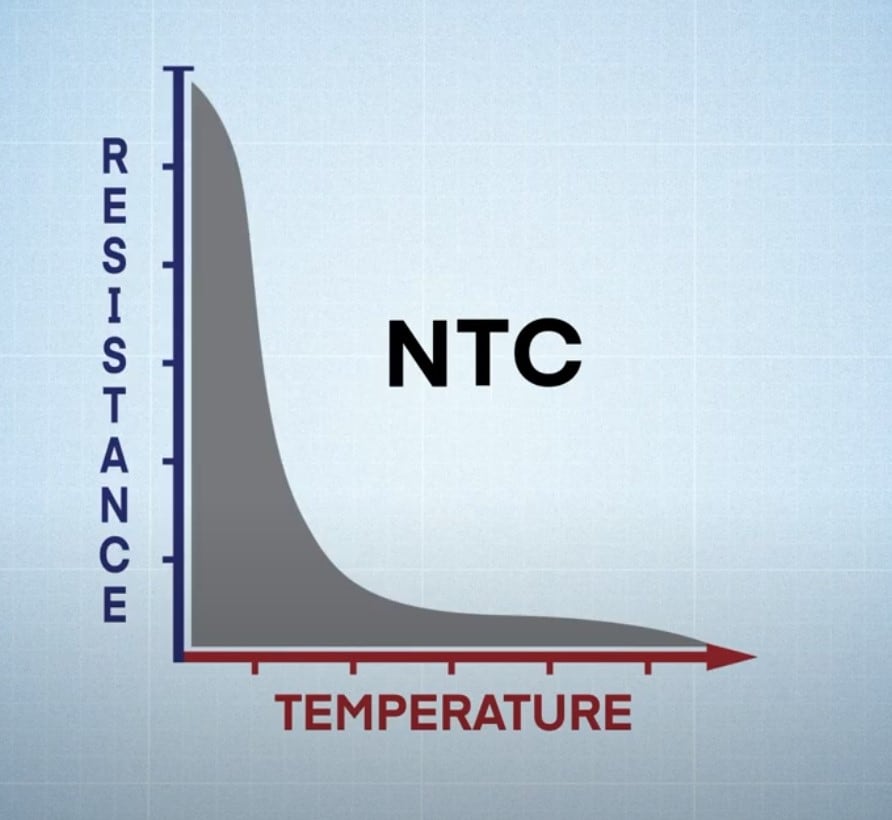

A thermistor works by changing its electrical resistance in response to temperature changes. Thermistors operate according to one of two principles: Negative Temperature Coefficient (NTC) or Positive Temperature Coefficient (PTC). Most thermistors have an NTC, meaning their resistance decreases as temperature increases. PTC thermistors are less common, and they behave in the opposite way: when temperature increases, the resistance increases, and when the temperature decreases, resistance decreases.

Steinhart–Hart Equation

The Steinhart–Hart equation is the widely accepted model for describing a thermistor’s resistance–temperature relationship. It relates the electrical resistance of the thermistor element to its absolute temperature:

Where:

- T = Temperature in kelvins (K)

- R = Thermistor resistance at temperature T (ohms, Ω)

- A,B,C = Steinhart–Hart coefficients provided by the manufacturer for a specified temperature range

Tolerance Curves

Accuracy tolerances for thermistor sensors are expressed as a percentage of temperature, a specification also referred to as interchangeability. In practice, a tolerance curve defines the allowable deviation between the thermistor’s actual resistance–temperature response and its nominal curve. This means a thermistor with a tighter tolerance curve will produce readings closer to the expected value without the need for calibration.

Tolerance is typically specified at a reference point, often 25 °C, with common values ranging from ± 0.1 °C to ± 1.0 °C. However, it is important to note that tolerance generally widens as the measured temperature moves further from the reference point. For example, a thermistor rated at ± 0.2 °C at 25 °C may only maintain ± 0.5 °C accuracy at the extremes of its operating range.

Because tolerance curves represent interchangeability, they play a crucial role in applications where thermistors must be replaced or swapped without recalibrating the system. Tighter tolerances allow greater interchangeability, which can reduce maintenance costs and simplify design for manufacturers.

Thermistor Construction and Materials

Thermistors are built from semiconductor materials designed to respond predictably to changes in temperature. The sensing element is typically composed of a blend of metallic oxides—such as manganese, nickel, cobalt, copper, or iron—combined with binders and stabilizers. These compounds are pressed into a bead, disc, chip, or wafer, then sintered at high temperatures to achieve the desired electrical properties.

Once formed, the thermistor element is coated for protection. Epoxy coatings are common for lower temperature applications, generally up to about 150 °C, while glass coatings extend the operating range to roughly 300 °C and provide greater resistance to humidity, corrosion, and mechanical stress.

The precise ratio of materials determines the resistance–temperature curve of the device, and manufacturers control these ratios with high accuracy to ensure consistent performance. This material science foundation is what gives thermistors their exceptional sensitivity and repeatability.

Thermistor Configurations

While the sensing principle remains the same, thermistors are available in a variety of physical configurations to meet the needs of different applications:- Hermetically Sealed Flexible Thermistors

- Bolt-On or Washer-Mounted Thermistors

- Surface-Mount Thermistors

- Probe-Style Thermistors

-

Encased in polymer jackets to resist moisture, oils, and chemicals. These are commonly used in corrosive or liquid environments such as industrial fluids or food processing.

-

Designed to be installed into threaded holes or secured with standard fasteners. Their small thermal mass enables rapid response to temperature changes, making them ideal for monitoring pipes, tanks, and equipment casings.

-

Built with adhesive backings that allow them to attach directly to flat or curved surfaces. These are popular in electronics, appliances, and compact systems where easy installation and repositioning are important.

-

Housed in metal or polymer probes that shield the delicate sensing element. Probe thermistors are suited for immersion in liquids, outdoor environments, or applications requiring repeated sanitization.

Innovative Solutions from DwyerOmega