Accurate measurement of thermal energy in hydronic heating and cooling systems is the foundation of meaningful energy analysis. Whether it's a commercial building or an industrial facility, precise thermal energy metering delivers the reliable data needed to evaluate efficiency and support energy conservation goals.

But how accurate are these meters, and what factors influence their performance?

What Is Thermal Energy and Why Measure It?

Thermal energy is the heat absorbed or released by a system, typically measured in British Thermal Units (BTU). In hydronic heating or cooling systems, measuring thermal energy helps determine how much energy the system is consuming, which in turn guides adjustments to maximize efficiency.

A thermal energy metering system generally consists of:

- A fluid flow sensor

- Two temperature sensors (inlet and outlet)

- A calculator that determines the thermal energy without manual computation

Thermal energy calculations are rooted in the first law of thermodynamics: with the fluid’s properties, flow rate, and the temperatures at the inlet and outlet, the system’s energy use can be determined.

Methods of Measuring Hydronic Thermal Energy

There are two common approaches:

- Traditional Method

- Flow meter and temperature sensors are separate

- Relies on a building management system to calculate thermal energy

- Each component is calibrated separately

- Complete System Method

- Combines the flow sensor, temperature sensors, and calculator in one unit

- All components are calibrated together as a system

- Provides a more streamlined and accurate measurement solution

Sources of Error in Thermal Energy Measurement

Both methods are subject to potential inaccuracies, but traditional setups are more prone to error due to separate calibration. Key sources of error include:

- Resolution limits of sensors

- Specific heat variations of the fluid

- Density variations of the medium

- Temperature sensor misalignment or separate calibration

A complete system reduces these risks because all components are calibrated together. This approach ensures better resolution, specific heat corrections, and density adjustments, leading to higher accuracy.

Global Standards for Heat Metering

Ultimately, accuracy is not left to chance. Over the past 25 years, international bodies have developed heat metering standards to regulate performance and promote trust in measurement data:

- OIML R75: First defined in 2002 by the International Organization of Legal Metrology

- EN 1434 (European Commission): The most widely adopted and specified standard globally

- ASTM E3137 / CSA 900.1-13: North American standards aligned with EN 1434

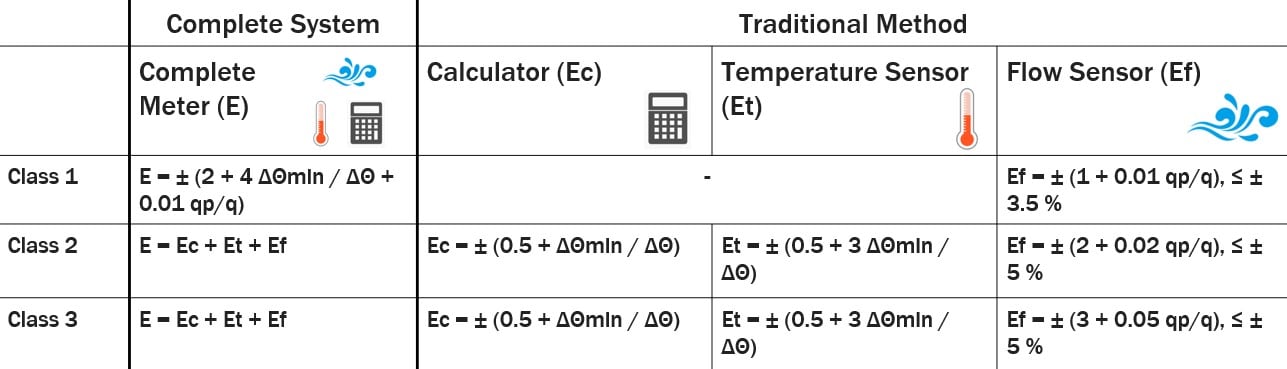

These standards define three accuracy classes:

- Class 1: Most accurate

- Class 2: Moderate accuracy

- Class 3: Least accurate

Only complete system meters can achieve Class 1 accuracy, since all three measurement components are calibrated together.

Why Accuracy Standards Matter

When selecting a thermal energy meter that complies with EN 1434, ASTM, or CSA accuracy classes, you can be confident that your energy readings are reliable, financial tracking of energy usage is precise, and environmental reporting aligns with global sustainability goals.

In addition, following these standards and participating in related energy certification programs can offer tangible benefits. Improved efficiency can lead to lower utility costs, while many organizations may also qualify for tax incentives or rebates designed to encourage energy conservation.

Featured Solutions from DwyerOmega

Series IEFB Thermal Energy Meter

For applications where accuracy and compliance with global standards are critical, the Series IEFB Thermal Energy Meter offers a complete solution. Unlike traditional setups that rely on separately calibrated components, the IEFB integrates an electromagnetic flow sensor, temperature sensors, and a calculator into a single unit. This design minimizes error sources and ensures consistent, reliable measurements.

The IEFB is built for versatility, with models available for pipe sizes from 100 mm to 900 mm (4 in to 36 in) and an easy-to-read LCD display that shows fluid velocity, temperature, and energy consumption in real time. Multiple output options—including selectable BACnet MS/TP or Modbus® RTU communications, along with analog, frequency, and alarm outputs—make integration with building automation and industrial control systems seamless.

Ideal for monitoring chiller and boiler performance, district heating and cooling networks, and energy cost allocation, the IEFB helps operators optimize energy use, reduce operating costs, and align with sustainability and efficiency goals.

Connect with a DwyerOmega Expert Today!