Next time you grab a bag of flour or sugar at the grocery store, consider the journey it took to get there. The small particle size of these materials requires specialized handling to ensure there is minimal damage or loss, which is called Pneumatic Conveying.

How Pneumatic Conveying Works

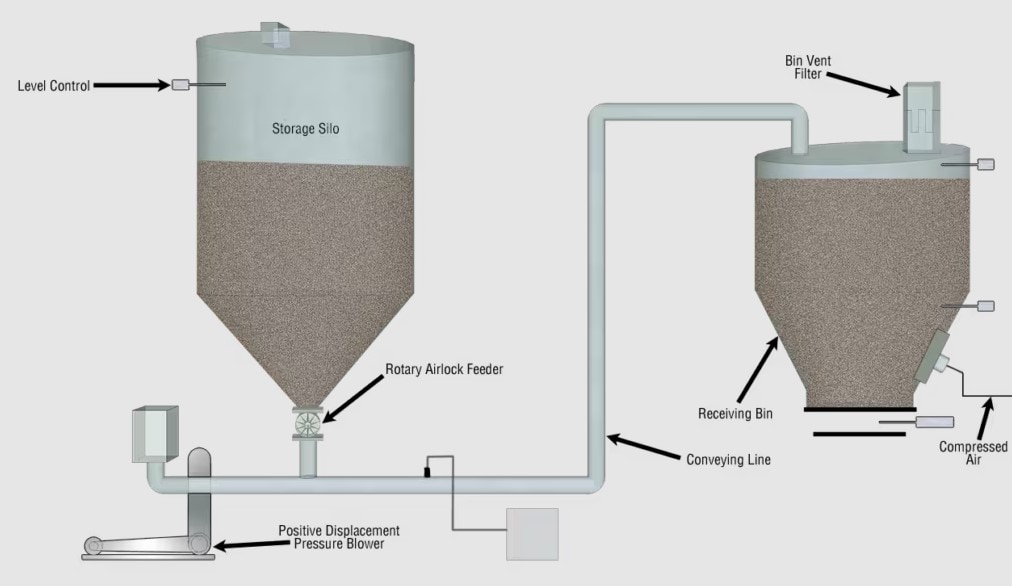

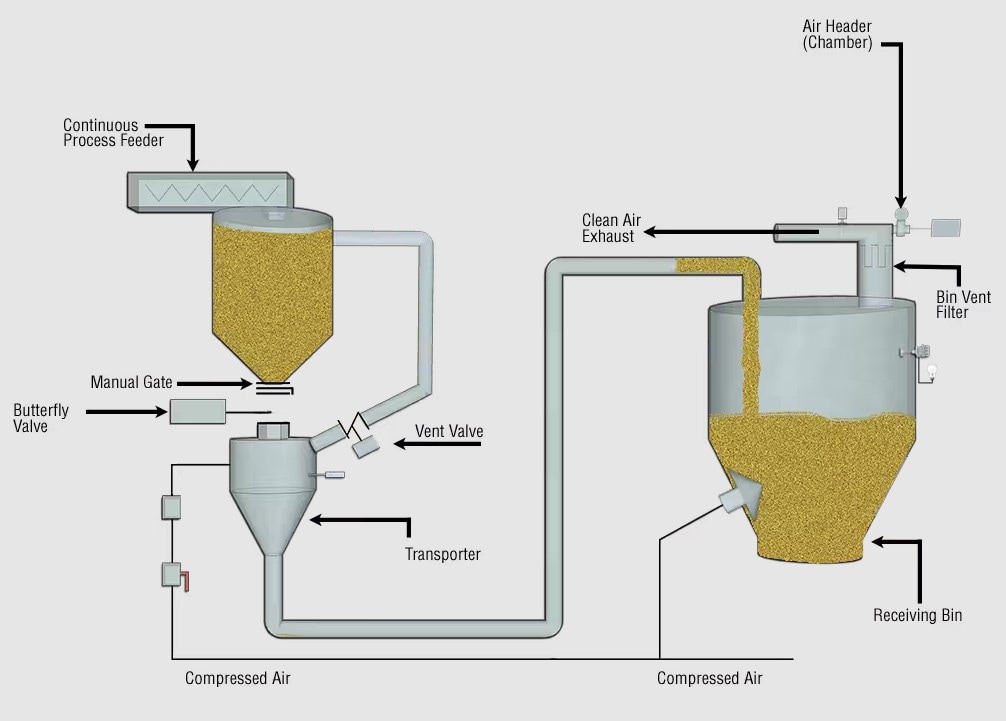

A pneumatic conveying system works by moving the material through an enclosed conveyor line using a combination of pressure differential and the flow of air (or another gas) from a blower or fan. Pneumatic conveying systems can be used to transport cement, starch, sugar, salt, polymers, plastic powder, and other powdered/granular bulk materials. The two most common forms of pneumatic conveying systems are Dilute Phase and Dense Phase.

Dilute Phase Conveying System

A dilute or lean phase conveying system utilizes a high volume of low pressure air, typically below 15 psig, or vacuum as the force to move powdered/granular bulk materials through an enclosed conveyor line. The high velocity air flow typical of a dilute phase system moves materials in an airborne state.

This option is cost-effective, and is well-suited for:

- Lightweight materials

- Non-abrasive substances

- Non-fragile powders or granules

Dense Phase Conveying System

In contrast, a dense phase conveying system moves powdered bulk materials using a small amount of air at a relatively high pressure, typically above 15 psig. These materials are gently pushed through the conveyor line in controlled slugs, similar to extruding. This method reduces friction and wear, making it ideal for:

- Abrasive or fragile materials

- Heavier bulk solids

Dense phase conveying offers gentle handling and better control, especially when material integrity is critical.

Featured Solutions from DwyerOmega

The Series AT-3000MR/MRS ATEX/IECEx Approved Photohelic® Switch/Gage combines a precise, repeatable differential pressure switch with a large, easy-to-read analog gauge, making it ideal for monitoring pressurized air in pneumatic conveying systems and other hazardous-area applications.

Designed for use with air and other non-combustible, non-corrosive gases, this unit offers both high and low limit control and continues to display accurate pressure readings even during power loss.

Two models are available:

- The AT-3000MR: Electromechanical relays for low-amperage (dry circuit) applications

- The AT-3000MRS: Solid-state relays for high-cycle switching without wear

A flameproof aluminum housing (with optional glass window) allows local visibility of process pressure and set points, while maintaining an IP66 rating when properly installed.

Key Features:

- Gauge unaffected by switch operation or power loss

- External zero and range adjustments—no disassembly needed

- Easy set point adjustment via front knobs (after de-energizing)

- Ideal for pneumatic conveying, clean rooms, HVAC, and fume control

Connect with a DwyerOmega Expert Today!