Next time you grab a bag of flour or sugar at the grocery store, consider for a moment the journey it took to get there. The small particle size of these materials requires specialized handling to ensure there is minimal damage or loss, a process called Pneumatic Conveying.

How Pneumatic Conveying Works

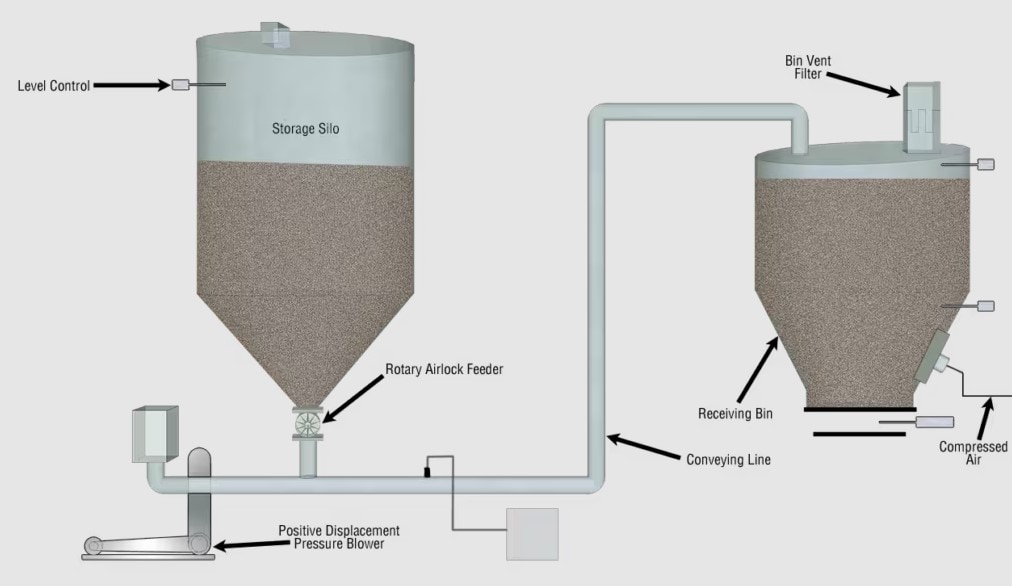

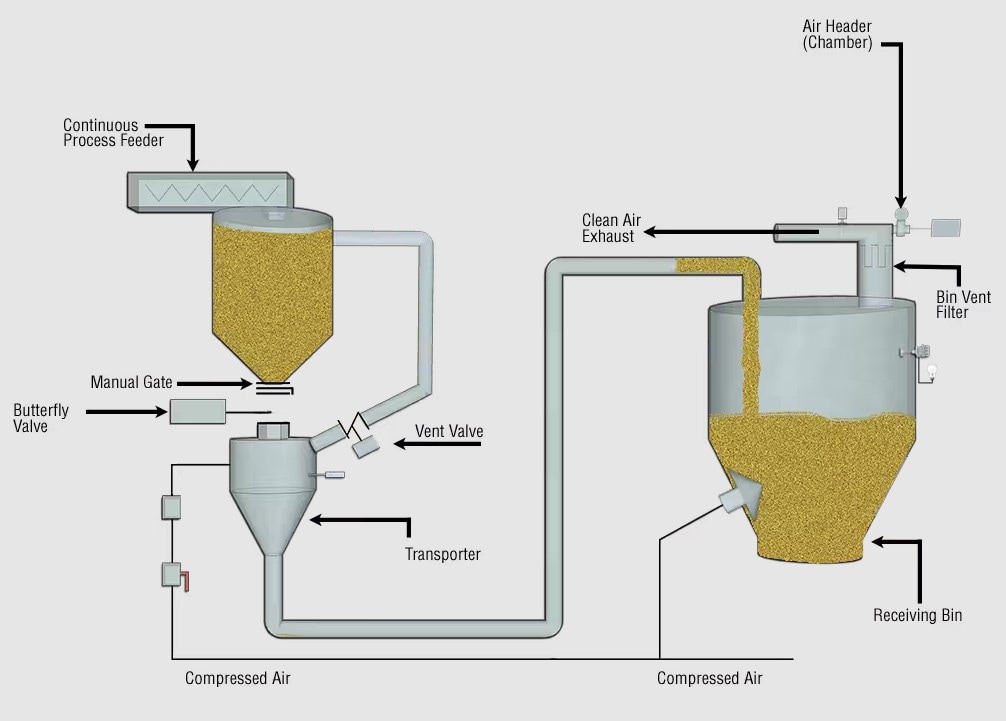

A pneumatic conveying system works by moving the material through an enclosed conveyor line, and does so through a combination of pressure differential and the flow of air (or another gas) from a blower or fan. Pneumatic conveying systems can be used to transport cement, starch, sugar, salt, polymers, plastic powder, and other powdered/granular bulk materials. The two most common forms of pneumatic conveying systems are Dilute Phase and Dense Phase.

Dilute Phase Conveying System

A dilute (or lean phase) conveying system utilizes a high volume of low pressure air, typically below 15 psig, or a vacuum as the force to move powdered/granular bulk materials through an enclosed conveyor line. The high velocity air flow typical of a dilute phase system moves materials in an airborne state.

This option is cost-effective, and is well-suited for:

- Lightweight materials

- Non-abrasive substances

- Non-fragile powders or granules

Dense Phase Conveying System

In contrast, a dense phase conveying system moves powdered bulk materials using a small amount of air at a relatively high pressure, typically above 15 psig. These materials are gently pushed through the conveyor line in controlled slugs, similar to extruding. This method reduces friction and wear, making it ideal for:

- Abrasive or fragile materials

- Heavier bulk solids

Dense phase conveying offers gentle handling and better control, especially when material integrity is critical.

Featured Solutions from DwyerOmega

PLS2 Paddle Level Switch

In pneumatic conveying systems that handle bulk solids, maintaining proper material levels in silos, bins, and hoppers is critical to prevent overfilling, flow interruptions, and equipment strain. The PLS2 Paddle Level Switch offers a reliable, low-maintenance solution for level detection in these applications.

This electromechanical switch is designed for durability in harsh environments and is well-suited for both mining and food processing operations.

Key Features:

- Proven Electromechanical Design

- Low-Maintenance Operation

- Versatile Mounting Options

- Rugged and Application-Ready

-

Utilizes a rotating paddle that stops and triggers a switch when obstructed by accumulated material—providing simple, mechanical level indication without complex electronics.

-

A brushless synchronous motor rotates the paddle at a slow 1 RPM, minimizing wear and extending service life.

-

Standard 1-1/4" male NPT connection allows for easy installation on the side or top of storage vessels.

-

Built for demanding conditions commonly found in pneumatic bulk conveying, especially for dry materials like powders, grains, pellets, or crushed minerals.

Common Applications Include:

- Bulk solids level detection in silos and hoppers

- Material handling in mining operations

- Level monitoring for grains, powders, and other dry goods in the food and beverage industry

MSX-Pro Differential Pressure Transmitter

In pneumatic conveying systems, accurate monitoring of air pressure and flow is essential for system performance, safety, and energy efficiency. The MSX Pro Magnesense® Differential Pressure Transmitter is designed to meet the high demands of critical environments with a flexible, installer-friendly design.

- Wide Range Versatility

- Flow and Velocity Output Options

- Durable, Tamper-Resistant Housing

- Dual Output Signals

- NIST-Traceable Calibration Available

-

Offers 32 selectable pressure ranges (Pa, mm w.c., and in w.c.) in both unidirectional and bidirectional modes—ideal for a variety of conveying and ventilation applications.

-

Provides linear pressure output or square root extraction for linear velocity and calculated flow—perfect for monitoring airflow in ducts or verifying flow rates in conveying lines.

-

Innovative design protects internal electronics during installation; flip-lid housing gives easy access to wiring without risking accidental damage.

-

Simultaneous voltage and 4-20 mA current outputs support integration with building automation and equipment control systems.

-

Optional NIST calibration provides added confidence for regulated environments and quality assurance processes.

Common Applications Include:

- Filter monitoring in air handler units

- Duct static pressure measurement in HVAC systems

- Air velocity and flow monitoring in VAV systems

- Building pressure control in cleanrooms

Connect with a DwyerOmega Expert Today!