Data centers are the core infrastructure behind our digital world. As they support everything from cloud services and streaming platforms to financial systems and industrial automation, their role has grown more critical and more complex.

Housing the servers, networking equipment, storage systems, and supporting infrastructure needed to store, process, and distribute large volumes of digital information, data centers must deliver reliable performance. In fact, with server racks pushing beyond 240 kW in high-density applications like AI, the need for precise environmental control has never been greater.

Maintaining uptime and efficiency requires more than just computing power. It calls for intelligent facility design, tight control over variables such as airflow, temperature, and humidity, and robust monitoring systems that provide real-time insight into conditions on the floor. From temperature sensors to differential pressure monitors, instrumentation plays a key role in keeping systems running smoothly and securely.

Monitoring Temperature and Humidity for Equipment Reliability

Excess heat and high relative humidity can compromise the performance and longevity of sensitive IT equipment. Studies from major data center operators, including IBM, have shown that poor control of these conditions increases the risk of hardware failure, reduces system efficiency, and contributes to unexpected downtime.

To help maintain optimal operating conditions, DwyerOmega offers robust sensing solutions designed for precise environmental monitoring. The Series RHP Humidity/Temperature Transmitter combines capacitive humidity sensing with accurate temperature measurement, offering ±2.5 % RH accuracy in a compact, configurable design. It’s ideal for monitoring hot and cold aisles, network closets, and other mission-critical zones within the data center.

For room-specific temperature tracking, the Series TE-E/N Wall Mount Temperature Sensor provides a cost-effective and reliable solution. Its low-profile enclosure blends easily into server rooms or control spaces, delivering accurate readings that support automated HVAC response and thermal regulation.

Airflow Monitoring to Support Efficient Cooling

Consistent and balanced airflow is critical to maintaining thermal stability in data centers. Poor air velocity control can lead to hot spots, reduced cooling efficiency, and overworked HVAC systems—compromising both energy usage and equipment health.

The Series AVUL and Series AVLV Air Velocity Transmitters are designed to accurately measure air velocity or volumetric flow within ductwork. These devices provide a reliable linear output that integrates easily with building management systems (BMS) for real-time control and analytics.

For data centers, the AVLV’s high-accuracy, low-range capabilities are particularly well-suited to quality-sensitive environments where precise airflow regulation is essential to cooling performance. By monitoring airflow through supply and return ducts, these transmitters help ensure efficient air distribution, improve energy optimization, and reduce the risk of thermal overload on critical infrastructure.

Differential Pressure Control for Clean and Balanced Airflow

In high-density data centers, even small fluctuations in airflow or static pressure can impact cooling efficiency, energy use, and equipment reliability. Monitoring differential pressure across air handling units, filters, and ductwork is essential for maintaining stable environmental conditions and ensuring clean, well-balanced airflow to server racks.

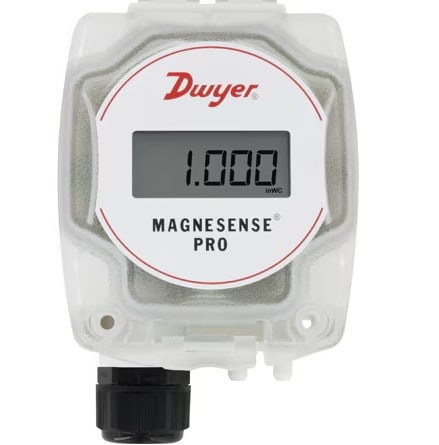

The Series MSX and Series MSX Pro Magnesense® Differential Pressure Transmitters deliver the high-accuracy pressure measurement required for these critical applications. Built-in square root capability allows the transmitter to convert velocity pressure into airflow or volumetric flow, reducing the need for additional instruments and simplifying BMS integration.

With dual voltage and current outputs, the MSX series supports both real-time system control and alarm notification. In data centers, these transmitters are commonly used to control variable frequency drive (VFD) air handlers and to monitor pressure drop across HVAC filters—ensuring proper airflow delivery while helping to maintain contaminant-free cooling.

Flow Monitoring for Critical Cooling System Uptime

Data centers rely heavily on liquid-based cooling systems to manage the high thermal loads generated by dense server environments. Ensuring consistent coolant flow—and the ability to service components without shutdown—is vital to maintaining uptime and preventing thermal events.

The Series IEF Insertion Electromagnetic Flowmeter is designed specifically for this type of application. Its hot-tap capability allows the sensor to be installed, removed, or replaced without interrupting the operation of chillers or taking the system offline. This enables maintenance teams to make adjustments or conduct replacements without risking server downtime.

For added redundancy, the IEF also offers a unique configuration option that allows three sensors to be installed in the same pipe location. This triple-sensor setup provides a critical layer of failover protection, ensuring continuous monitoring even if one flowmeter requires service—an ideal solution for mission-critical environments like data centers where reliability is non-negotiable.

Connect with a DwyerOmega Expert Today!