1-800-663-4209 | Welcome to our new website, found an issue or bug? Please report it here

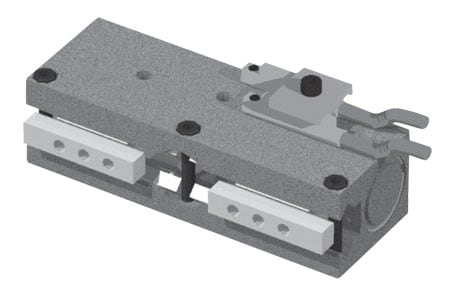

RPL-Series

Parallel Pneumatic Grippers - Low Profile, Force 116 to 160 N

- Precision Gripping-Preloaded V Roller Bearings Eliminate Side Play Resulting in Excellent Part Positioning

- Gripper Force 116 to 160 N (26 to 36 lbs) Stroke 6.4 to 19.1 mm (0.25 to 0.75')

- Accuracy of 0.05 mm (0.002') and Repeatability of 0.03 mm (0.001')

- Rigid and Low Friction Design Allows for Longer Finger Lengths for Use on Delicate Parts

Product Overview

- Additional Features 1 Precision Low Profile Series

- Cylinder Type Dual Double acting

- Filter 40 Micron or better

- Height 19.1 mm

- Kit Description Seal Repair Kit: Available; Field Repairable: Yes

- Mechanical Life 5 million cycles

- Operating Environment 4-way, 2-position

- Operating Pressure, Max 7 bar

- Operating Pressure, Min 0.3 bar

- Operating Temperature, Max 80 °C

- Operating Temperature, Min -35 °C

- Repeatability ±0.03 mm

- Seal Options Internally lubricated Buna-N

RPL Series Gripper is a pneumatic parallel gripper with excellent parallelism and accuracy between the gripper mounting surface and jaw surface. Jaws are front mounted and are supported with 'Dual-V' roller bearings to provide low friction motion and are preloaded for maximum support and zero side play. This gripper supports longer finger length designs compared to other grippers of similar sizes. These grippers are available in stroke lengths from 6.4 to 19.1mm (0.25 to 0.75') with a grip force from 116 to 160 N (26 to 36 lbs).

Linear motion pneumatic components are double acting cylinders that require a dry air supply with filtering to 40 microns or better. For best control of pneumatic components, flow control valves (regulating out) should be installed to regulate the speed of the device. Position sensors can easily be added to motion components to detect the end of travel positions of the slides, they are the standard method of communication with the PLC and are available in inductive or magneto resistive sensing styles and come in both PNP or NPN sourcing signals.

Linear motion pneumatic components are double acting cylinders that require a dry air supply with filtering to 40 microns or better. For best control of pneumatic components, flow control valves (regulating out) should be installed to regulate the speed of the device. Position sensors can easily be added to motion components to detect the end of travel positions of the slides, they are the standard method of communication with the PLC and are available in inductive or magneto resistive sensing styles and come in both PNP or NPN sourcing signals.

PDFs & Manuals

Accessories

Show Ratings & Reviews