A thermocouple is a thermoelectric device that is used to measure temperature. Valued for their simplicity, durability, and wide operating ranges, thermocouples consist of two dissimilar metal wires. When one connecting junction of those wires experiences a different temperature than the other, a small voltage is generated. Because this voltage changes predictably with temperature, thermocouples provide a reliable way to monitor everything from industrial processes and HVAC systems to laboratory equipment and high-temperature furnaces.

How Does a Thermocouple Work?

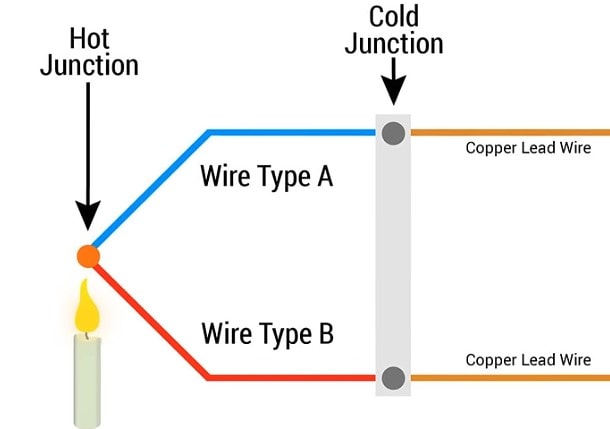

A typical thermocouple consists of two dissimilar metal wires joined together at both ends. One junction is placed in the medium or on the surface that is being measured (this is known as the hot junction), while the other end (called the cold junction) is connected to a thermocouple-compatible device (such as a meter, a controller, or a transmitter) that remains at a constant, known temperature.

When the hot junction experiences a temperature change, the heat causes the electrons within each metal wire to move. Because the two wires that make up any given thermocouple are made from different alloys, their electrons move at different rates. This creates a measurable millivolt signal between the two conductors: the wire whose electrons move more freely develops a negative charge at the cold junction, while the other becomes the positive lead.

From this difference in potential, the device calculates temperature using a formula that converts the millivolt output into a temperature value.

Thermocouple Types and Ranges

There are many different thermocouple types, and they are defined by their metal combinations. Each thermocouple alloy combination determines its temperature range and sensitivity. These combinations are standardized and represented by letter designations. The most common are the base metal thermocouples:

- J J Type J (Iron-Constantan)

- K K Type K (Chromel-Alumel)

- T T Type T (Copper-Constantan)

- E E Type E (Chromel-Constantan)

- N N Type N (Nicrosil-Nisil)

* Left badge represents ANSI color code; right badge represents IEC color code.

Among these, Type K Thermocouples are the most widely used due to their low cost, versatility, and wide temperature range, making them ideal for general-purpose temperature measurement.

Thermocouple Styles

Thermocouples are available in a variety of mechanical styles, each designed for specific installation requirements and measurement conditions. Two of the most common constructions are the probe-style thermocouple and the surface-style thermocouple, which are defined by how the sensing junction is built and where the sensor is intended to be used.

Thermocouple Probes

A probe-style thermocouple encloses the sensing junction inside a protective metal sheath, typically made from stainless steel or other high-temperature alloys. This sheath shields the junction from mechanical damage, moisture, and corrosion, making the probe suitable for immersion, insertion, and penetration applications. Because of its tubular, protected design, a thermocouple probe is generally placed directly into a fluid, solid, or gaseous medium to measure the internal process temperature. In simple terms, a probe is a thermocouple built into a durable, insertable metal tube.

Probes with Lead Wires

Lead-wire thermocouples provide flexible installation and are commonly used in industrial, laboratory, and HVAC settings. The extended leads make it possible to measure temperatures in confined or distant locations where direct access is limited, maintaining reliable performance across varied conditions.

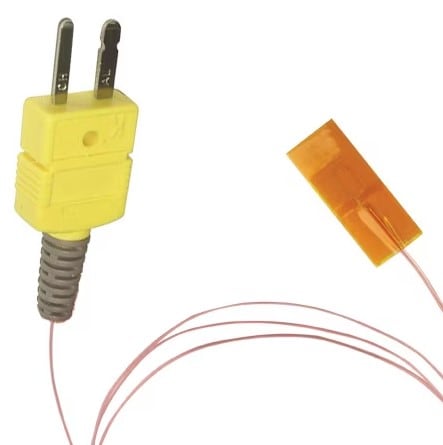

Probes with Connectors

Thermocouple probes equipped with connectors allow quick, secure attachment to instruments such as controllers, transmitters, or data loggers. They are often chosen for industrial monitoring, laboratory testing, and HVAC control, where ease of connection and replacement are important.

Probes with Protection Heads

Protection-head thermocouples are designed for harsh or high-temperature environments, such as process lines, furnaces, and chemical systems. The metal head protects the junction and wiring from physical damage, dust, and moisture, while also providing a junction block for stable electrical connections.

Probes with Handles

Handle-style thermocouple probes are used for portable or handheld temperature measurement. They are common in industrial inspection, laboratory testing, and food processing, where quick, accurate spot checks are required without permanent installation.

Multi-Point Profile Probes

Multi-point thermocouple probes contain several sensing junctions along a single probe, enabling measurement at multiple depths or locations within a process. They are used in reactors, furnaces, and storage tanks to monitor thermal gradients and ensure uniform temperature distribution.

Probes with Sanitary Flanges

Sanitary-flange thermocouples are designed for hygienic applications in food processing, pharmaceutical, and biotechnology industries. Their smooth surfaces and CIP/SIP compatibility help prevent contamination while maintaining precise temperature measurement under strict cleanliness standards.

Probes with Vacuum Flanges

Vacuum-flange thermocouples are used in vacuum-sealed environments such as semiconductor fabrication and research laboratories. They maintain vacuum integrity while providing accurate temperature readings under low-pressure conditions.

Surface Thermocouples

A surface-style thermocouple is constructed so that the sensing junction sits against the exterior surface of a solid object rather than inside the material. These sensors use flat, exposed, spring-loaded, magnetic, or washer-shaped contact designs to ensure good thermal contact with the surface. Since they are not inserted into the medium, surface thermocouples are intended strictly for surface temperature measurement, providing rapid response and minimal thermal lag. Put simply, a surface thermocouple is built to rest on or press against the outside of an object to measure its surface temperature.

Mountable Surface Thermocouples

Mountable surface thermocouples are built for continuous, fixed-position monitoring on equipment surfaces. They are commonly used in industrial machinery, HVAC components, and automotive systems where long-term temperature tracking is required. These sensors can be installed on either flat or curved surfaces, providing stable, repeatable measurements once secured in place.

Portable Surface Thermocouples

Portable surface thermocouples are designed for quick, handheld temperature checks during inspections, diagnostics, or field testing. Their compact construction allows technicians to obtain fast, accurate surface temperature readings without permanent installation. This style is frequently used in industrial maintenance, HVAC troubleshooting, and general inspection work where mobility and rapid response are essential.

Thermocouples in Action: Common Thermocouple Applications

Rugged, cost-effective, and reliable, thermocouples are widely used throughout numerous industries and applications for temperature measurement and process control. Their ability to withstand harsh environments, respond quickly to temperature changes, and interface easily with controllers, transmitters, and data loggers makes them a universal sensing solution.

HVAC Systems

Thermocouples are used throughout HVAC systems. They help maintain consistent environmental conditions, optimize system efficiency, and protect equipment from overheating. Common applications include supply and return air temperatures, boiler and chiller monitoring, and duct temperature profiling in both commercial and industrial facilities.

Industrial Ovens and Furnaces

In high-temperature applications such as metal heat treatment, ceramics, and glass manufacturing, thermocouples provide accurate and repeatable temperature feedback for process control. Type K and Type N thermocouples are especially common due to their high-temperature stability and resistance to oxidation. Their readings ensure that heating cycles remain within precise temperature tolerances, critical for achieving material strength and consistency.

Food & Beverage Processing

Accurate temperature measurement is essential in ensuring product safety and quality during cooking, pasteurization, freezing, and storage. Thermocouples are ideal for these applications because they offer fast response times and can be fabricated in sanitary probe configurations for compliance with FDA and HACCP standards. They are also used in ovens, fryers, and packaging systems to verify that products remain within specified temperature limits.

Injection Molding

Thermocouples are integral to the plastic injection molding process, where they monitor barrel, nozzle, and mold temperatures to maintain material quality and uniform part production. Real-time feedback allows controllers to adjust heater bands and coolant flow automatically, preventing defects such as warping or incomplete fills.

Innovative Solutions from

TCS-H-NB9W Series Sanitary Thermocouple Sensors

TCS-H-NB9W Series Thermocouple Sensors are designed for sanitary applications in the food, beverage, dairy, and pharmaceutical industries. Built with 316L stainless steel construction, these probes ensure cleanability and compatibility with hygienic process systems.

Each sensor features a smooth 32 microinch or better surface finish in all wetted areas, making them suitable for environments where hygiene and sterilization are critical. The design includes a 1½-16 AMP sanitary flange as standard, with additional flange sizes and configurations available to meet specific system requirements.

Connection options include a white polypropylene screw-top head (NB9W) or a stainless steel screw-top head (NB15), both supporting straightforward wiring to process instrumentation. Available in Type T, J, and K thermocouple sensor styles (as well as RTD configurations), these assemblies offer flexibility across a wide range of sanitary process monitoring needs.

SA3 Series Self-Adhesive Surface Thermocouples

The SA3 Series Surface Thermocouple provides fast, reliable temperature measurement using a low-mass junction bonded to a flexible polyimide carrier. A self-adhesive backing allows these sensors to be easily applied to flat or curved surfaces without clamps or additional hardware.

Designed for demanding environments, these sensors are resistant to oils, chemicals, moisture, and outdoor exposure, including direct sunlight. Their thin profile and minimal thermal mass enable rapid response to surface temperature changes, making them well-suited for testing, diagnostics, and monitoring applications.

SA3 models are available with either stripped #30 AWG solid leads or a miniature color-coded connector, offering convenient integration into a wide range of instrumentation setups.