A load cell is a type of transducer that converts mechanical force into a measurable electrical signal. Depending on its construction, a load cell can measure tension, compression, shear, or torque. That electrical output can then be calibrated and converted into a precise force or weight value.

Load cells are used in any application where force measurement is critical, including industrial weighing, materials testing, structural monitoring, automation, and process control.

How Do Load Cells Work?

Load cells operate by translating applied mechanical force into an electrical output that can be read, recorded, and analyzed by instrumentation or control systems. The exact internal mechanism depends on the operating principle of the load cell.

While designs vary, most load cells rely on a predictable physical change that occurs when force is applied, such as deformation, pressure change, or variation in an electrical property. That change is then converted into an electrical signal proportional to the applied force.

Innovative Solutions from

Common Load Cell Operating Principles

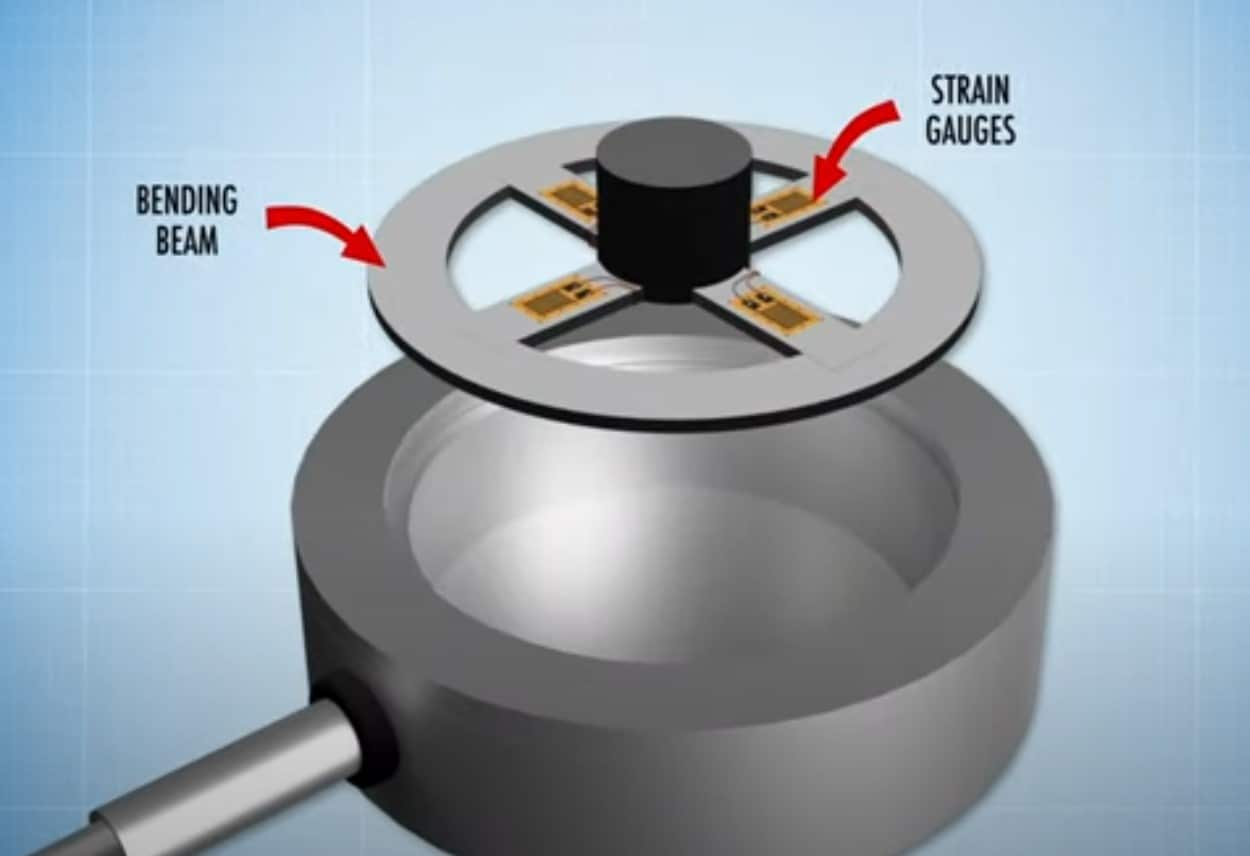

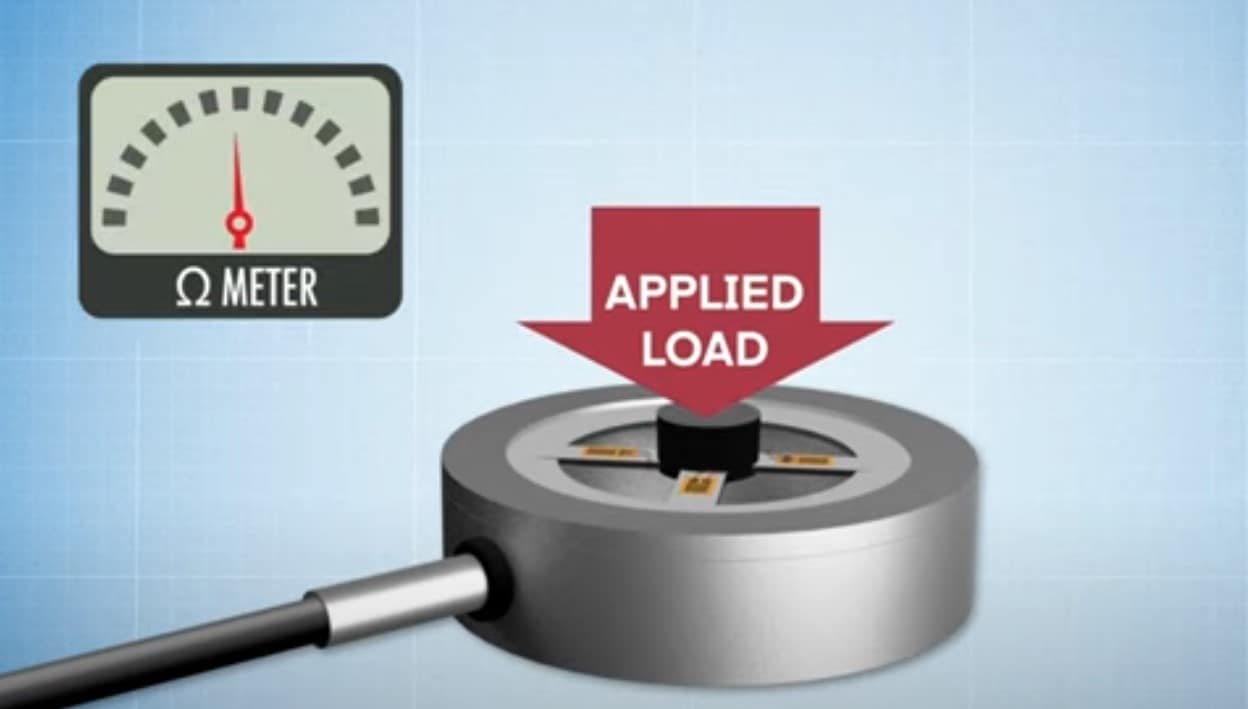

Strain Gauge Load Cells

Strain gauge load cells are the most widely used type due to their accuracy, stability, and repeatability. Strain gauges are bonded to a beam or structural element that deforms slightly when force is applied. This deformation causes very small changes in electrical resistance. Those resistance changes are converted into a voltage signal that is proportional to the applied force and can be precisely measured.

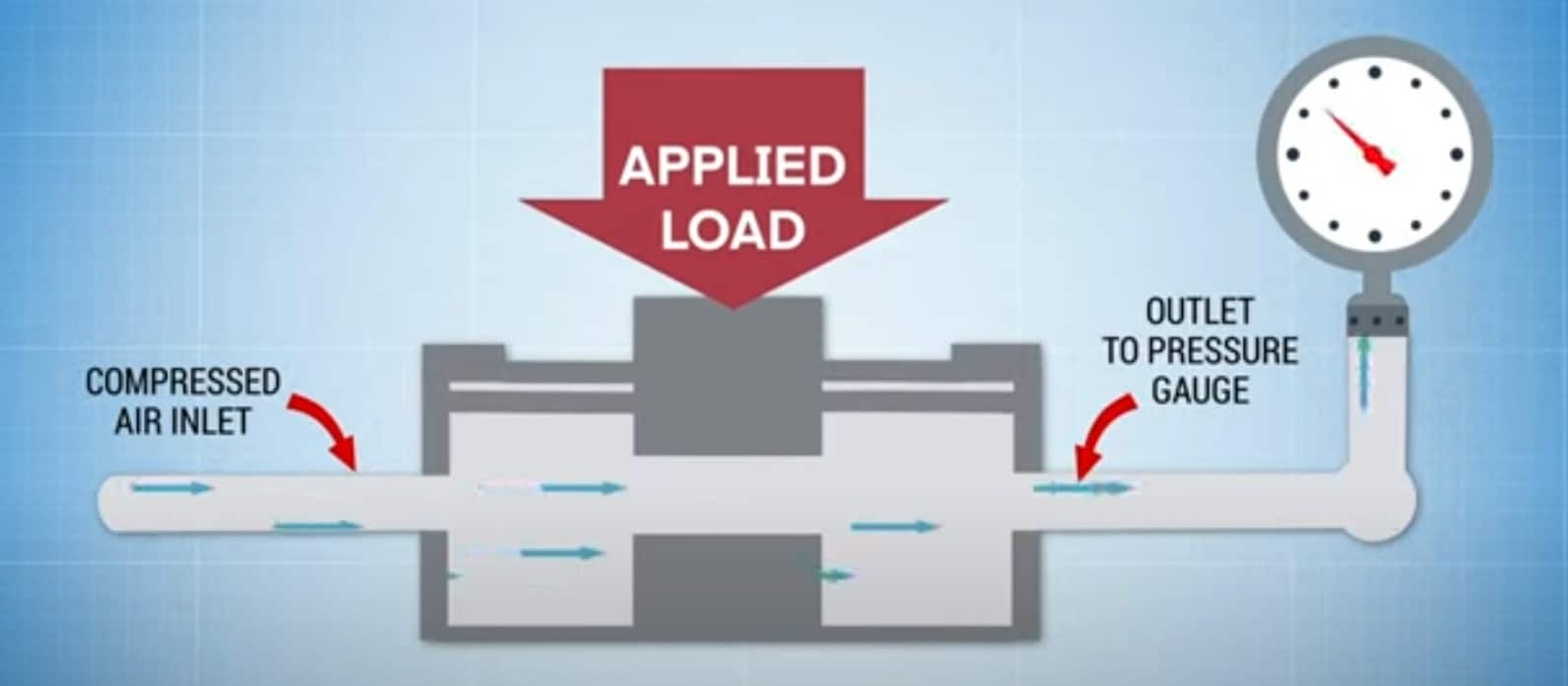

Pneumatic Load Cells

Pneumatic load cells use pressurized air or gas to counterbalance an applied load. The amount of air pressure required to balance the force is correlated to the load being measured. These load cells are often used in hazardous environments where intrinsic safety is required because they do not rely on electrical components at the sensing point.

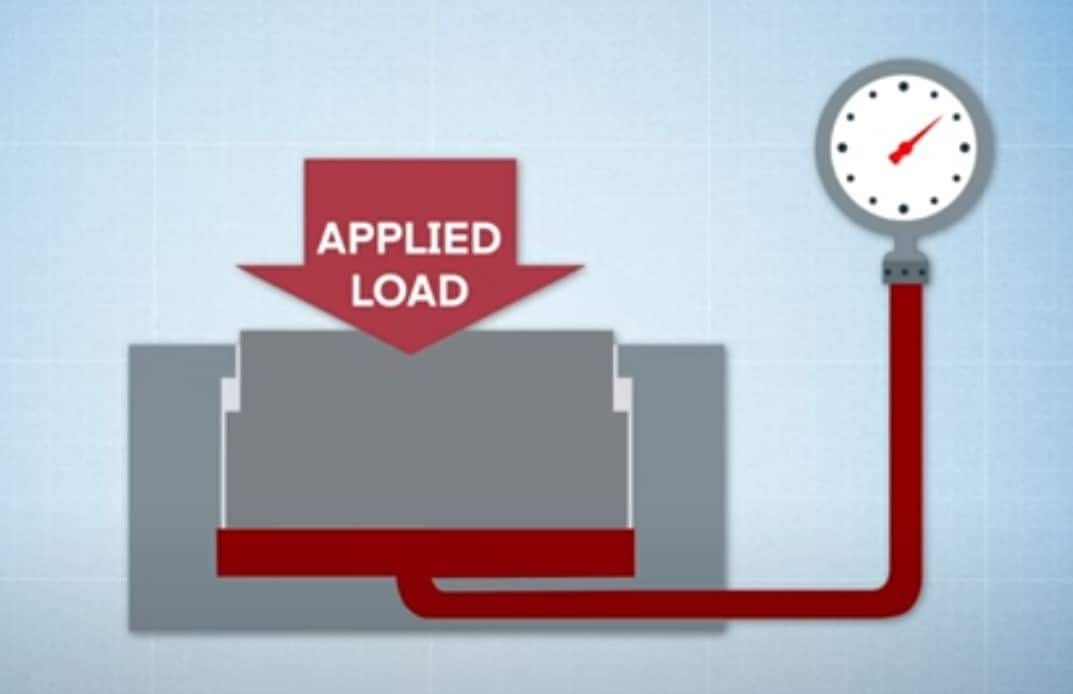

Hydraulic Load Cells

Hydraulic load cells operate by applying force to a piston that compresses a fluid, typically oil or water. The resulting increase in fluid pressure is directly proportional to the applied load. Hydraulic load cells are commonly used in heavy load applications where electrical power may be limited.

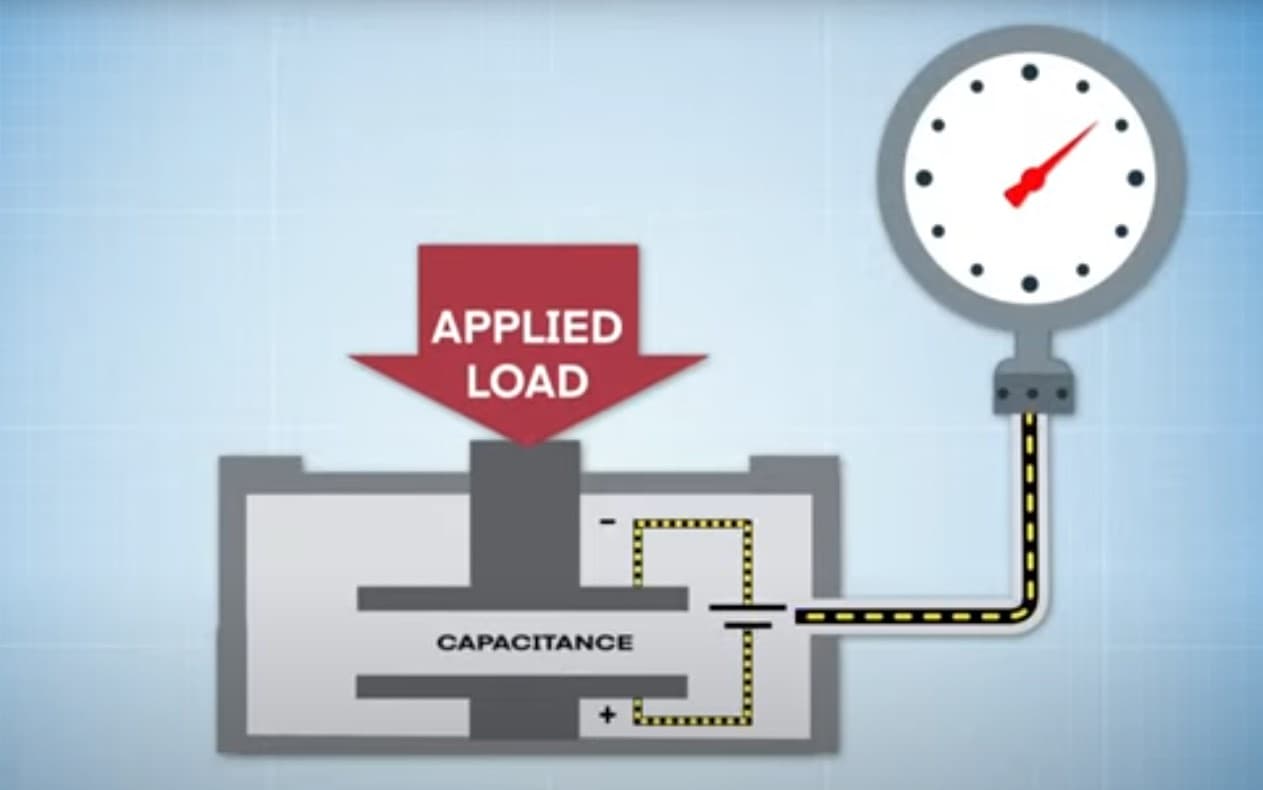

Capacitive Load Cells

Capacitive load cells measure force by detecting changes in capacitance between two parallel plates. When force is applied, the distance between the plates changes, altering the capacitance. That change is converted into an electrical signal related to the applied load.

Click to learn more about types of load cells.

Common Load Cell Designs and Configurations

S-Beam Load Cells

S-beam load cells are designed to measure both tension and compression. They are commonly used in suspended load applications, such as hanging tanks, hopper scales, and material testing setups.

Miniature Compression Load Cells

Miniature compression load cells are built for applications with limited space. They provide accurate compression force measurement in compact assemblies, laboratory equipment, and embedded mechanical systems.

Tension Link Load Cells

Tension link load cells are used to measure tensile forces in cables, chains, and support rods. They are frequently used in lifting, rigging, and structural load monitoring applications.

Bending Beam Load Cells

Bending beam load cells feature a low-profile design and are often used in platform scales, industrial weighing systems, and OEM equipment where space constraints are a concern.

Load Cell FAQs

Answer: Load cells are used in a wide range of applications where force or weight must be measured accurately and reliably. Common applications include industrial weighing, material testing, process control, automation, and safety monitoring.

Different applications use different load cell types based on how the force is applied. Platform scales, tank and hopper weighing systems typically use compression or shear beam load cells. Hanging scales, crane systems, and suspended loads use tension or S-beam load cells. Single-point load cells are common in bench scales and packaging equipment, while pancake and low-profile load cells are used in applications with limited vertical space or high load requirements.

Answer: Strain gauge load cells work by converting mechanical deformation into an electrical signal. When a force is applied, the metal sensing element of the load cell flexes slightly under tension or compression.

Strain gauges bonded to this sensing element stretch or compress along with the material, causing a small change in electrical resistance. These resistance changes are arranged in a Wheatstone bridge circuit, producing a proportional voltage output. The signal is then amplified, calibrated, and processed to provide an accurate force or weight measurement.

Answer: Troubleshooting load cell signal issues starts by verifying the mechanical installation and electrical connections. The load cell must be mounted correctly, loaded only in its intended direction, and free from binding, off-axis forces, or mechanical interference that can distort the signal.

Next, check the electrical side of the system. Inspect wiring for loose connections, damaged cables, or moisture ingress, and confirm that the excitation voltage and signal output match the load cell specifications. Zero drift, unstable readings, or no output at all can often be traced to improper grounding, electrical noise, overload damage, or incorrect calibration. Recalibrating the system with known weights and confirming proper signal conditioning typically resolves most load cell signal problems.