The primary purpose of a clean room is to control and limit airborne particulates within a defined space. These particulates may include sub-micron dust, pathogens, chemical vapors, or moisture droplets that can compromise sensitive manufacturing processes.

Clean rooms are widely used across industries such as semiconductor fabrication, pharmaceutical production, and medical device manufacturing, where even minor contamination can result in product failure or yield loss.

Among all the variables that define clean room performance, maintaining a consistent differential pressure between the clean room and adjacent spaces is the most critical.

Why Differential Pressure is Essential in Clean Rooms

A pressure difference between a clean room and the surrounding areas, often an anteroom or corridor, is needed to prevent infiltration of unwanted particulate matter.

When a clean room is maintained at a positive pressure relative to the adjacent space, air naturally flows outward through door gaps, seals, and openings. This outward airflow prevents contaminated air from entering the controlled environment. A familiar example of this principle occurs when entering a building on a windy day and feeling air push outward as the door opens. The building interior is at a higher pressure than the outside air.

Clean rooms operate under the same physical principles but at much smaller pressure differentials. Typical clean room pressure setpoints range from 0.02 to 0.05 inches of water column, depending on the cleanliness classification and application requirements. Although small, this differential is sufficient to maintain directional airflow and protect the clean space from contamination.

How Differential Pressure Sensors Provide Solutions in Clean Rooms

Positive pressure within a clean room is typically achieved using a fan or blower as part of a variable air volume (VAV) system. By increasing the amount of supply air delivered to the room, the system raises the internal pressure relative to adjacent spaces.

A differential pressure sensor, such as a room pressure monitor, room status monitor, or differential pressure transmitter, continuously measures the pressure difference between the clean room and the anteroom. This measurement is sent to a direct digital controller (DDC), which adjusts the VAV system accordingly:

- If pressure drops below the setpoint, airflow is increased

- If pressure rises too high, airflow is reduced

Why Sensor Stability Matters

Clean room pressure control operates within an extremely narrow operating window. Because the acceptable pressure range is so small, sensor stability over time is just as important as initial accuracy.

If a differential pressure sensor drifts due to aging, contamination, temperature effects, or internal component instability, it may continue reporting a value that appears valid but no longer reflects actual room conditions. When this happens:

- The VAV system may deliver too much air, increasing turbulence and energy consumption

- Or it may deliver too little air, reducing the pressure barrier that keeps contaminants out

Because of this, long-term stability is a critical performance requirement for clean room pressure sensors, not just resolution or accuracy at installation.

Innovative Solutions from DwyerOmega

Series MSX Pro Magnesense® Differential Pressure Transmitter

The Series MSX Pro Magnesense® Differential Pressure Transmitter is designed for critical clean room and controlled-environment applications where long-term stability and reliable pressure control are essential. It combines the proven versatility of the Magnesense platform with enhanced stability, simplified configuration, and added physical security for regulated facilities.

Key Features

- Exceptional pressure stability for clean rooms and other critical environments

- Flip-lid housing for fast, easy access to wiring terminals

- Tamper-resistant cover for added security and protection

- Simplified ordering and configuration to reduce setup time

- Supports Pa, mm w.c., and in. w.c. units with 32 selectable pressure ranges

- Configurable for unidirectional or bidirectional pressure measurement

- Linear pressure or linear velocity output with onboard square-root extraction

Common Applications

- Differential pressure monitoring in pharmaceutical and semiconductor clean rooms

- Building pressure control in critical environments

- Filter monitoring in air handling units

- Duct static pressure measurement

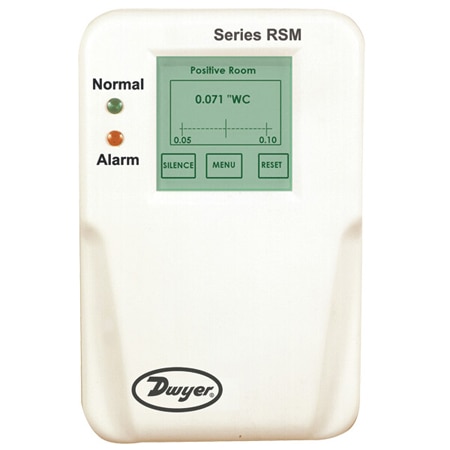

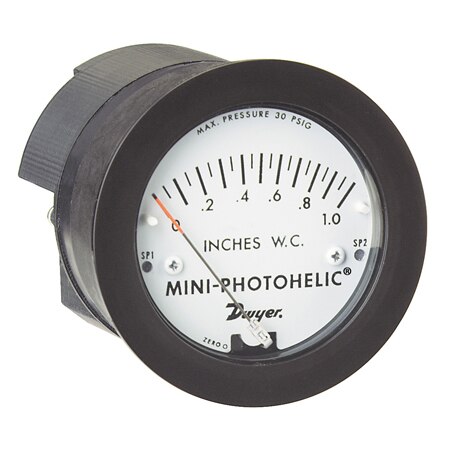

Series MP Mini-Photohelic® Differential Pressure Switch/Gage

The Series MP Mini-Photohelic® Differential Pressure Switch/Gage combines continuous visual pressure indication with integrated switching control in a compact, panel-mount device. Designed for non-corrosive, non-combustible gases, it provides reliable monitoring and alarm functionality for clean rooms and other controlled environments.

Key Features

- Combines a Minihelic® II differential pressure gage with two SPDT switch set points

- Gauge reading remains accurate and visible regardless of switch operation or power loss

- Front and rear LEDs provide clear indication of switch status

- Push-button set point adjustment on the rear of the unit

- Measures positive, negative, or differential pressure

Common Applications

- Clean room pressure monitoring

- Fume hoods

- Dust collection systems

- Pneumatic conveying systems

Additional Parameters Commonly Controlled in Clean Rooms

While differential pressure is foundational to clean room performance, it is rarely the only parameter being monitored. Depending on the application and cleanliness classification, additional environmental variables may include:

- Temperature: to ensure process consistency and equipment reliability

- Relative humidity (RH): to prevent electrostatic discharge or condensation

- Volatile organic compound (VOC) levels: particularly in pharmaceutical and chemical processes