Air balancing is the process of testing, adjusting, and verifying airflow in an HVAC distribution system to ensure it performs according to design. Proper air balancing ensures that every zone, each room, and all terminal devices receive the correct volume of conditioned air, typically measured in cubic feet per minute (CFM) or cubic meters per hour (m³/h).

Without proper balancing, even a well-designed HVAC system can suffer from:

- Uneven temperature distribution

- Comfort complaints

- Poor indoor air quality

- Excess energy consumption

- Reduced equipment life

How Airflow Is Measured During Balancing

To balance airflow accurately, technicians must first measure it. Two traditional measurement methods are commonly used:

Flow Hoods at Terminals

An air flow hood, also called a capture hood, directly measures volumetric airflow at registers, grilles, and diffusers. Flow hoods align to ceiling registers.

While convenient, placing a flow hood over a terminal introduces back pressure into the duct system. This added resistance can temporarily reduce airflow, leading to measurement errors. Some digital flow hoods include back pressure compensation algorithms to reduce this effect.

Duct Traverse Measurements

Another accepted method is performing a duct traverse using:

These instruments measure velocity pressure or air velocity within the duct to calculate actual airflow. Many technicians perform a duct traverse to verify system performance or confirm correction factors before using a hood.Traditional Proportional Balancing

Proportional balancing is the most widely used air balancing method in HVAC systems.

System Preconditions

Before beginning proportional balancing, the total system airflow must fall within 80 % to 120 % of design airflow. If the system operates outside this range, fan speed must be adjusted first. A system outside this range cannot be proportionally balanced correctly.

How Proportional Balancing Works

In proportional balancing, one terminal is selected as the key terminal. Other terminals are adjusted relative to this reference point.

For example:

- Terminal 1 design flow = 60 %

- Terminal 2 design flow = 57 %

- Ratio = 57 / 60 = 0.95

If Terminal 1 is adjusted to deliver 100 % of design flow, Terminal 2 should deliver 95 % of its design flow.

Limitations of Proportional Balancing

This process:

- Requires multiple adjustment iterations

- Relies on technician estimation

- Can introduce cumulative tolerance errors

- Becomes time-consuming in larger systems

Predictive Balancing

Predictive balancing is a deterministic method designed to reduce the number of iterative steps required during testing, adjusting, and balancing.

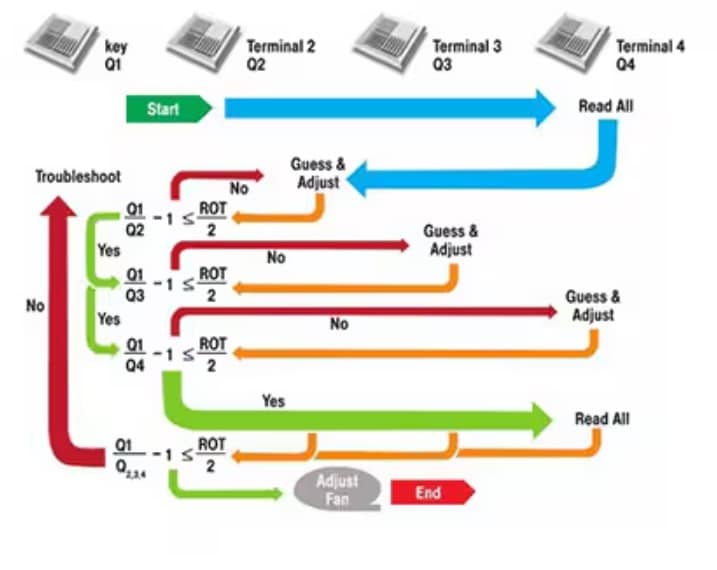

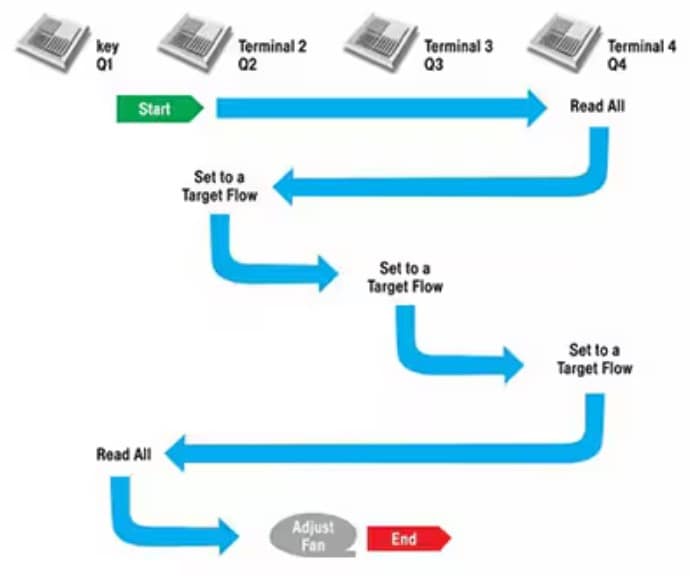

How Predictive Balancing Works

The process begins by fully opening dampers to capture total airflow. The total airflow is then distributed across terminal units based on:

- Damper position

- Terminal load

- System pressure drop

Instead of adjusting terminals proportionally and iterating, predictive balancing:

- Calculates the ideal flow set point for the terminal under adjustment (TUA)

- Predicts how other terminals will respond

- Guides the technician directly to the correct damper position

-

Terminal 2 is adjusted first, and the method then predicts the resulting flow changes at Terminals 1, 3, and 4. Using those calculated values, the next terminal can be adjusted systematically, eliminating guesswork and ensuring a more efficient and accurate balancing process.

Advantages of Predictive Balancing

Compared to proportional balancing, predictive balancing:

- Reduces field adjustment time

- Minimizes iteration cycles

- Compensates for fan load changes during damper closure

- Improves repeatability

- Enhances overall balancing accuracy

Why Proper Air Balancing Matters

Regardless of the method used, proper air balancing is essential because HVAC systems rarely operate under ideal theoretical conditions. In real-world installations, performance is influenced by installation variations, duct leakage, construction tolerances, equipment performance variation, and system modifications made over time. These factors can significantly affect how air is distributed throughout a building, often resulting in deviations from the original design intent.

Effective balancing ensures that design airflow is delivered to each zone, comfort levels remain consistent, energy consumption is optimized, and equipment operates within its intended performance parameters. In critical environments such as hospitals, laboratories, clean rooms, and data centers, airflow imbalance is more than a comfort issue. It can directly impact safety, regulatory compliance, and mission-critical operations.

Innovative Solutions from DwyerOmega

Series SAH SMART AIR HOOD® HVAC Balancing Instrument

The Series SAH SMART AIR HOOD® streamlines air balancing by enabling one technician to complete testing, adjusting, and balancing without a second operator. With integrated Wi-Fi connectivity and Predictive Balancing software, the instrument reduces labor time while improving measurement efficiency.

The low-profile hood design allows use in occupied spaces such as bathroom stalls, MRI rooms, cubicles, and tight mechanical areas. Quad Flow Design Technology minimizes back pressure to improve volumetric airflow measurement accuracy. The lightweight, ergonomically balanced construction reduces technician fatigue during extended balancing sessions.

Using the included 12 ft extendable pole and wireless communication to an Android® or iOS® device, a single operator can receive real-time airflow data from up to 200 yards (183 m) away. This eliminates repeated ladder climbs when adjusting dampers and speeds up the balancing process.

Key Features:

- Enables single-technician air balancing

- Wi-Fi connectivity with mobile device interface

- Quad Flow Design Technology reduces back pressure

- Low-profile hood for tight or occupied spaces

- Predictive Balancing software optimizes adjustment order

- Lightweight, ergonomic design

- NIST traceable certificate included

Series-160 Stainless Steel Pitot Tube for Airflow

The Series-160 Stainless Steel Pitot Tube is designed for accurate air velocity and airflow measurement in demanding industrial and HVAC applications. Constructed from corrosion-resistant stainless steel, the tube features permanently etched insertion depth graduations to ensure long-term durability and repeatable positioning.

The ASHRAE-style tip design eliminates the need for calibration while maintaining high measurement accuracy. Low sensitivity to misalignment, up to 15 degrees, allows for reliable readings even when installation conditions are not ideal. The static pressure port is parallel to the sensing tube, enabling quick and accurate alignment with airflow.

Silver-soldered connections provide leak-proof operation, and 5/16 in models are rated for temperatures up to 1500°F (815.5°C), making the Series-160 Stainless Steel Pitot Tube suitable for high-temperature duct systems and industrial environments. A universal model is available to fit user-supplied 3/4 in schedule 40 pipe in any length.