Netherlands 07077 03815 | Intl +31 (0) 7077 03815 | Welcome to our new site - found a bug? Please report it here

LVU500-Series

Reflective Ultrasonic Level Transmitter with Alarm for Small Tanks

- Designed to handle condensing environments

- Offered in 1.5 m (4.9’) and 3 m (9.8’) measurement ranges

- Fail-safe diagnostics with 4 selectable relays and signal outputs

- Narrow 2” (5 cm) beam width for applications with limited space

LVU500-Series

From

C$

782.30

Product Overview

- Approvals ul61010_1

- Beam Width 2 in

- Cable Length 48 in

- Cable Type Insulated Shielded

- Configuration WebCal® PC Windows® USB® 2.0

- Contact Fail-Safe Open, Closed, Hold Last

- Diameter 2.9 in

- Electrical Output 4 to 20 mA

- Enclosure Ratings NEMA 6 to 30P for 240V

- Height 4 in

- Insulation Polyurethane

- Loop Resistance 500 Ω @ 24 Vdc

- Materials FKM, Fluoroelastomer, Polycarbonate, Polyvinylidene, Fluoride

- Mean Hysteresis Selectable

- Media Compatibility Alkaline solutions, Dilute Acids, Hydraulic Oil, Light Oil, Oil, Solvents, Water, Water-based fluids

- Memory Non - Volatile

- Number of Wires 2

- Operating Pressure, Max 30 psi

- Operating Temperature, Max 60 °C

- Operating Temperature, Min -35 °C

- Output Signal Current

- Process Connection Size 2 in

- Process Temperature, Max 80 °C

- Process Temperature, Min -40 °C

- Signal fail-safe 4 mA, 20 mA, 21 mA, 22 mA or hold last

- Signal invert 4 to 20 mA or 20 to 4 mA

- Supply Voltage 14 to 28 Vdc

- Switch Rating 60 VA,1A max

- Switch Type SPST

- Temperature Compensation Automatic

- Transducer Type Reflective Ultrasonic

The LVU500 Series general purpose reflective ultrasonic multi-function level transmitter provides continuous level measurement up to 3 m (9.8) with a 4-20 mA analog signal output and four relays and is configured via web calibration software. The non-contact liquid level sensor features our proprietary Reflective Technology® that delivers reliable level measurement in condensing environments. Each relay can be configured for alarm, automatic fill or empty functions. Select this sensor for small tanks with chemicals, water, wastewater and oil (non-foaming and/or highly vaporous liquids). Typical applications include day tank, IBC or drum, cooling tower, skid or machine, process tank and waste sumps.

Applications:

Day tank, skid or machine, cooling tower, IBC or drum, process tank, small waste sump

Configuration:

The sensor is configured via our WebCal software and one Fob USB adapter. WebCal is a PC utility program that allows users to easily configure their sensors, update firmware, save configurations and print wiring schematics prior to installation. WebCal is a free download from our website.

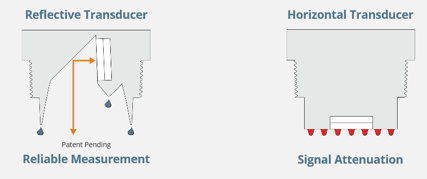

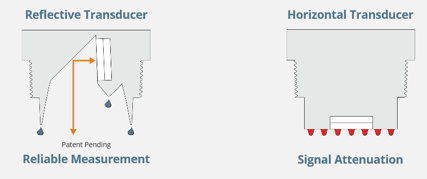

Reflective Technology ®

Condensation is the most common issue for ultrasonic level transmitters. Condensation attenuates the acoustic signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise ratio by up to 50%, and substantially reducing their measurement reliability. At the core of Reflective Technology® is a simple fact. Unlike flat horizontal surfaces, significant water droplets cannot adhere to smooth vertical surfaces. By orienting the transducer vertically, condensation runs off the transducer and does not affect sensor performance. The unimpeded transmit and receive signals are redirected to and from the liquid off a 45 º reflector, delivering reliable level measurement.

Applications:

Day tank, skid or machine, cooling tower, IBC or drum, process tank, small waste sump

Configuration:

The sensor is configured via our WebCal software and one Fob USB adapter. WebCal is a PC utility program that allows users to easily configure their sensors, update firmware, save configurations and print wiring schematics prior to installation. WebCal is a free download from our website.

PDFs & Manuals

Software & Drivers

Accessories

accessories

Show Ratings & Reviews