1-800-663-4209 | Welcome to our new website, found an issue or bug? Please report it here

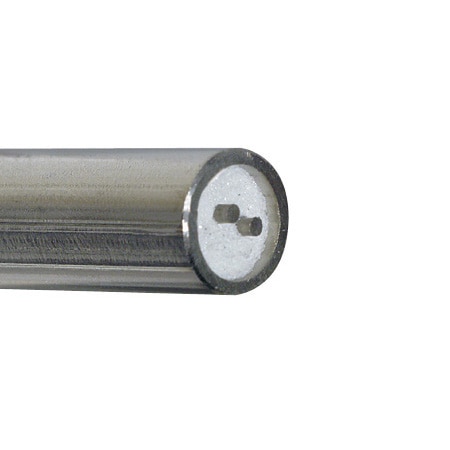

SUPER-OMEGACLAD-XL

XL Sheath Mineral Insulated Thermocouple Wire

- Excellent Long Term Stability at High Temperatures

- Continuous use up to 1150°C

- Excellent Oxidation, Carburization and Chlorination Resistance

- High Purity MgO (HP) Available

SUPER-OMEGACLAD-XL

From

C$

2.40

Product Overview

- Density 8.5 g/cu3

- Electrical Resistivity 698 Ω-cir-mil ft

- Elongation 0.80

- Insulation MgO

- Modulus Of Elasticity 137 Gpa

- Process Temperature, Min 0 °C

- Series ID SUPER-OMEGACLAD-XL

- Temperature Sensor Type Thermocouple

- Tensile Strength 50 MPa

- Thermal Conductivity 36.7 W/m-K

XL Sheath Mineral Insulated Thermocouple Wire features a Nickel-Chrome Omegaclad XL sheath with compacted MgO mineral insulation and thermocouple calibrated conductors. It offers excellent long-term stability at high temperatures, continuous use up to 1150°C, and superior resistance to oxidation, carburization, and chlorination. High purity MgO insulation is also available for enhanced performance.

PDFs & Manuals

Show Ratings & Reviews

Rated 4 out of

5

by

Haejun Park from

lack of information

you need to introduce relevant accessories along with this wire.

Date published: 2022-03-05

How long are these TCs? Is this per foot, per inch...? Is it just wire? Is one end welded at a TC? What are you selling/what am I buying?

This is thermocouple wire in a metal sheath that is sold by the foot. It does not come with finished or welded end.

Date published: 2020-04-02

Can I get this MI cable with a calibration certificate? If so, what is the added cost for this certificate and how do I place my order to request this certificate?

Thank you for your inquiry. Please email your request to sales@dwyeromega.com

Date published: 2023-12-05

What is the total length? How long is it??? (XL Sheath Mineral Insulated Thermocouple Wire, K type, Dia: 1mm, Chromel-Alumel)

Thank you for your inquiry CAhn. There is no pre determined length of this wire since it is sold by foot/meter depending on the units. For example, qty of 1 = 1 foot/meter of the wire.

Date published: 2022-03-23

What is the thermal conducivity of the MgO powder used for insulation ?

Hi Bast04,

Thank you for the inquiry.

Thermal conductivity ranges from 30 W /m x K

Best regards,

OMEGA

Date published: 2022-01-20

What is the breakdown voltage of the mineral sheathing near room temperature? Can the nichrome shell be at several hundred volts with respect to the thermocouple wires?

Insulation Resistance is 1000 M ohm @ 500 volt dc for sheath diameters larger than 1.5 mm

500 M ohm @ 50 volt dc for sheath diameters between 1.5 and 0.8 mm

100 M ohm @ 50 volt dc for sheath diameters smaller than 0.8 mm

Date published: 2020-02-12