Industrial refrigeration supports food safety, pharmaceutical preservation, and process consistency, but true refrigeration reliability depends on precise, verifiable temperature control. Modern systems have evolved far beyond basic thermostats, integrating advanced sensors, intelligent controllers, and data validation tools that work together to maintain safety, efficiency, and regulatory compliance across every stage of operation.

Refrigeration and cold storage systems today utilize a network of specialized instruments working in concert to achieve that level of precision. From primary control loops that regulate compressors and valves, to independent safety switches and validation loggers that verify performance, each component plays a distinct role in maintaining stability. Together, these devices form a layered approach to temperature management, one that not only controls but also monitors, protects, and documents every stage of the refrigeration process.

Innovative Solutions from DwyerOmega

The following devices—from high-accuracy controllers and temperature switches to portable and high-temperature data loggers—represent the core technologies that enable consistent, verifiable temperature management in modern refrigeration environments.

CNI-Series Universal Input High Accuracy Controllers

In any industrial refrigeration system, maintaining precise temperature stability depends on accurate feedback and responsive control. The CNI-Series delivers both, serving as the primary temperature controller for coolers, freezers, and process environments where reliability and repeatability are non-negotiable.

Key Features:

- Universal Input Flexibility: Accepts thermocouples, RTDs, strain gages, voltage, and current signals for seamless integration across system types

- Exceptional Accuracy: ± 0.03 % of reading and ± 0.03 % of range, ensuring dependable temperature and process stability even under fluctuating loads

- Smart Control Options: PID, on/off, reverse, or direct action modes let engineers fine-tune compressor, valve, and heater response

- Visual Status Feedback: Programmable color display provides real-time visual alarms and easy parameter viewing

- Connectivity Options: Available Ethernet and serial communication enable remote monitoring, data logging, and supervisory integration

Application

The CNI-Series Universal Input Process Controller forms the core of a refrigeration system, providing precise regulation for coolers, freezers, and temperature-controlled process rooms. Ideal for cold storage warehouses, walk-in coolers, and industrial freezers, it maintains tight temperature setpoints to prevent product spoilage and ensure consistent operation.

In food and beverage plants, CNI Series controllers can regulate glycol loops or brine chillers that support blast freezers and ice makers. OEMs and process equipment builders use these controllers to maintain temperature compliance in pharmaceutical cold rooms and municipal water treatment chillers. They are also widely implemented in semiconductor manufacturing environments to manage chilled water loops and thermal control of process chambers, where stability and accuracy are essential for both cooling performance and product yield.

By maintaining stable operation under varying loads and ambient conditions, the CNI-Series helps reduce equipment wear, minimize downtime, and safeguard product quality across a broad range of refrigeration and process applications.

Series TS2 Digital Temperature Switch for Heating and Cooling

Compact, accurate, and easy to integrate, the Series TS2 is designed for dependable heating and cooling control across a wide range of refrigeration and temperature-sensitive applications. From medical sterilizers and food service equipment to refrigerators, chillers, and OEM systems, the TS2 provides precise temperature switching in a durable, user-friendly package.

Key Features:

- Flexible Operation: Ideal for both heating and cooling modes, ensuring precise temperature regulation in dynamic environments

- Quick Configuration: A convenient configuration key allows fast parameter setup and easy transfer between multiple units, perfect for OEM or multi-system installations

- Reliable, Durable Design: IP64-rated front panel resists dust and splashes, maintaining performance in demanding industrial and commercial conditions

- User-Friendly Interface: Three-digit LED display provides instant visibility of system status and setpoints

- Non-Volatile Memory: Retains all settings through power interruptions, ensuring system stability and reducing reconfiguration time

- Certified Performance: CE and cURus approvals confirm compliance with international safety and quality standards

Application

The the Series TS2 excels in refrigeration systems, food storage units, and medical equipment where accurate, repeatable temperature switching is essential for safety and efficiency. Its SPDT relay output allows direct control of compressors, fans, or heaters, making it an ideal local safety or backup controller in larger refrigeration systems.

Commonly installed in reach-in coolers, refrigerated display cases, and rooftop HVAC units, the TS2 provides reliable backup protection against sensor or controller failure. In supermarkets and restaurants, it serves as a safety cutoff to prevent over-temperature incidents that could compromise food safety. Manufacturers also integrate the TS2 into packaged refrigeration equipment as a dependable, low-cost safeguard.

Engineers and facility managers rely on the Series TS2 to maintain consistent performance, protect sensitive inventory, and streamline maintenance across multi-unit installations.

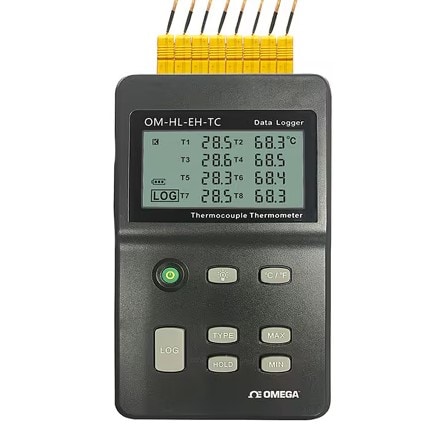

OM-HL-EH-TC-Series 8-Channel Handheld Thermocouple Thermometer/Data Logger

The OM-HL-EH-TC Series provides a portable, high-capacity solution for both routine audits and in-depth temperature studies. Designed for convenience and accuracy, this eight-channel handheld thermometer/data logger supports multiple thermocouple types and delivers real-time insight into system performance.

Key Features:

- Multi-Channel Versatility: Accepts eight thermocouple inputs (K, J, E, T, R, S, N, B) for simultaneous measurement across different zones or equipment

- Extensive Data Logging: Each channel stores up to 86,000 data points, with sampling intervals adjustable from 2 seconds to 24 hours

- High-Resolution Display: Large LCD provides real-time readings with MAX, MIN, and HOLD modes for quick field reference

- Flexible Power Options: Operates on internal battery or USB/DC power for portable or continuous use

- Comprehensive Data Management: Includes OM-HL LogPro software for downloading, analyzing, and exporting data in Excel, PDF, or graphical formats

Application

Essential for QA and compliance teams in food processing, cold storage, and distribution environments, this portable thermometer/data logger allows technicians to verify control sensor accuracy using calibrated probes during system audits, commissioning, or HACCP verification. Its lightweight, handheld design also makes it ideal for laboratory and test facility use, where engineers troubleshoot refrigeration cycles and confirm that both air and product temperatures remain within required compliance standards.

OM-CP-HITEMP140 Series Autoclave Temperature and Pressure Data Logger

When refrigeration, freezing, or pressurized cooling processes demand absolute proof of performance, the OM-CP-HITEMP140 Series delivers laboratory-grade precision in a field-ready package. This rugged, stainless steel data logger is engineered for extreme environments where accuracy, durability, and traceability are essential—from autoclave validation and blast chiller studies to high-pressure cooling and process verification.

Key Features:

- Rugged Construction: IP68-rated stainless steel housing withstands submersion, high pressure, and sustained operation up to 140 °C (284 °F)

- Dual-Parameter Capability: Measures both temperature and pressure (up to 5 bar), providing comprehensive process validation data

- Exceptional Accuracy: ±0.1 °C (0.18 °F) precision ensures compliance with the most stringent regulatory and quality standards

- Extensive Data Capacity: Stores up to 32,700 time-stamped readings for long-duration validation or audit applications

- Serviceable Design: User-replaceable battery and optional configurations (flush mount or 1/8-NPT port) for flexible installation and maintenance

Application

The OM-CP-HITEMP140 Series is ideal for verifying cooling and sterilization performance in blast chillers, brine tanks, autoclaves, and pressurized refrigeration systems. Specialized for environments where core product validation is required, it enables engineers and QA professionals to record precise temperature–pressure profiles and confirm that each equipment cycle meets operational and regulatory thresholds. In frozen food processing, the HITEMP140 verifies that chilling cycles meet standards designed to prevent microbial growth, while in semiconductor and automation industries, it supports refrigeration system validation where time–temperature profiles are critical for process quality. Whether used in food, pharmaceutical, or advanced manufacturing applications, this data logger provides complete confidence in process integrity and compliance documentation.

Connect with a DwyerOmega Expert Today!